How 4D Technology’s Metrology Equipment Improves Aircraft Inspection Procedures

Key Highlights

- 4D Technology's handheld, portable devices like InSpec and InSpec XL provide quick, accurate measurements of complex surfaces and textures in shop environments.

- Enhanced metrology reduces rework, scrap, and inspection time, leading to significant cost savings and improved aircraft safety.

- Automation and rapid training make these tools practical for widespread adoption in aviation repair stations, MROs and manufacturing facilities.

Improved metrology equipment for dimensional inspection has saved aviation companies time, money and effort when inspecting aircraft for defects.

Vice President of 4D Technology Erik Novak recently shared expertise on effective dimensional inspection in a webinar entitled “Accuracy of Shop-Floor Measurement of Roughness, Defects, and Small Geometries.”

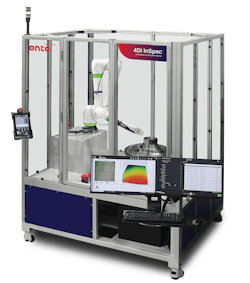

Novak explained that 4D Technology, a division of Onto Innovation, specializes in vibration immune 3D measurement systems and has used their systems to measure telescopes to the nanometer level.

He shared, “Over the last few years, we have taken those technologies used for testing optics and move them more into the industrial space, testing aircraft engines and automotive paint and other things.”

Why is effective dimensional inspection important in aviation?

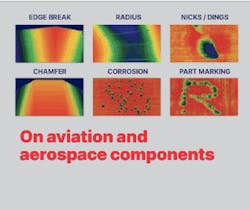

Discussing aerospace defect and dimensional inspection, Novak said, “There's the macro dimensions, but micro scale features really have a huge effect on longevity performance and customer perception. And that can be anything in the MRO world from wear scars to pitting and corrosion.”

He continued, “Even on newly made parts, you have nicks, dents, scratches. Chamfers and radii are critical for the efficiency of engines, for longevity, for the safety of people—weld bead profiles, shot peening coverage, rivet geometries—all of those things are very important and not measured very well with traditional techniques.”

Novak also mentioned a key challenge that occurs in aviation defect inspection, which involves inspectors following what he described as, “when in doubt, throw it out.”

He elaborated, “Some places talk about inspection being a committee event where multiple people will look at a part, and they'll debate whether it's good or bad and then eventually dispose of the part, one way or another, usually erring on the side of projecting or reworking, particularly in aviation.”

Novak also outlined the external factors that impact the effectiveness of inspections, such as:

- Customer perceptions

- Repair and service charges

- Post warranty costs

- Downtime

- Travel and return time

He explained that these factors can also impact long-term revenue and cause more short-term issues than the internal costs themselves.

How are dimensional measurements usually performed in aviation?

Novak went into some of the traditional solutions for inspecting for defects, roughness and small features. He said, “On the quick and cheap side of the fence, you have visual testing, fingernail testing, and it's essentially free, using the human brain to make dispositions.”

He added, “But while you can typically tell when things are very bad, you don't have a quantitative record of what they are. It's hard for other people to validate those results, and a lot of times it's just not good enough for the specifications coming in online now.

“You can go to more sophistication—replication and then using shadow graphs or 2D stylus systems—and there, you start getting into decent repeatability, decent accuracy, but typically still not gauge-capable and also quite expensive on materials on the replicas side, or for broken styli on the stylus side, and they can be problematic as well.”

Novak presented an alternative, sharing, “On the other end, you have 3D microscopes. They're way more accurate than is typically needed in micro-scale inspection. They go down sometimes to single nanometers, and that usually isn't needed.”

He continued, “And they're vastly expensive. They're $100,000 or more in cost, and they're slow and need sophisticated operators. A lot of times, they're in metrology labs, so you don't get the feedback you need.”

How can aviation repair shops improve the accuracy of measurements?

Reflecting on these challenges, Novak stressed the need for a solution that’s accurate and repeatable while remaining economical, portable and practical for aircraft inspections.

“If you don't know what's going on, you have a huge gray area between good and bad, said Novak, “And when you improve metrology, you reduce uncertainty to a very narrow band and can measure things right up to the specification level, which is enormously powerful.”

“That’s where we come into 3D optical gauging, which provides easy, accurate shop floor measurements,” Novak said, highlighting how new products and tools have been developed to benefit inspectors in aviation repair shops and MROs.

He continued, “And they were developed in partnership with the world's largest aerospace, engine and fuselage manufacturers. They required something that's handheld and portable. It needs to be easy to use, I was told, if it's much harder than taking a picture with a cell phone, don't bother.”

Novak outlined some needs for these systems, such as:

- Robustness: They may be dropped or banged around in the shop and on metal parts.

- Automation: They need to be automatable to keep up with industry trends.

- Practicality: They need to be handheld and able to measure any surface and texture.

Novak expanded on practicality, highlighting the need for devices that can navigate into small spaces as well as onto large parts. He noted they also need to be able to measure surfaces and textures like:

- Rubber

- Metal composites

- Painted surfaces

- Unpainted surfaces

How is 4D Technology addressing challenges in dimensional inspection?

Novak then discussed the solutions 4D Technology provides to address these challenges.

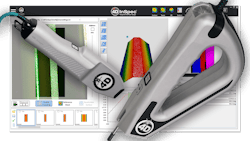

InSpec and InSpec XL Features

He shared, “On the defect and geometry side, we have the InSpec and the InSpec XL. They're both handheld units. One has about twice the field of view of the other.”

Novak called out features of the InSpec and InSpec XL, such as:

- Vertical resolution of a few microns

- Vertical range of many millimeters

- Acquisition time of less than one second

InSpec and InSpec XL Applications

“All these systems are vibration immune,” said Novak, “They don't need a lab. They can be placed on the part or held next to the part, so they're portable. They can be on microscope stands and robotic cells, and they serve a variety of applications.”

Novak explained, “You have workbench options. These are being used in production. If you're measuring the same blades or other parts over and over again, just set it up on a workbench as if it were a 3D microscope.”

He continued, “But the most common use is to put it on a cart and roll it around the shop floor, right up to whatever part needs to be measured. If you're doing on-wing…and other places with limited access…there's a backpack kit with a ruggedized tablet, and then you can go into full automation.”

Applications on the InSpec and InSpec XL that Novak listed included:

- Rivets and welds

- Scratches

- Cooling holes

- Edge break and radii geometry defects

“And being an optical technique, you can measure straight on. You can measure into corners. You can use a full mirror to measure up and into very difficult places,” added Novak.

How InSpec and InSpec XL Work

Novak explained, “You get a full field measurement—so either a tenth of an inch or a third of an inch, depending on which model you have—but in this case, in one field of view, we're actually measuring over 100 different features.”

Novak added, “They can be sorted by depth. They can be sorted by area. You can look at the total aerial coverage—because sometimes for corrosion, it's not just about how deep it is but how much of the area got corroded. All of these are database-able. You can have pass/fail criteria assigned to them, and you get your result in seconds.”

“We developed a surface gage that gives people the ability to calibrate the instrument and make sure that it's measuring accurately on a variety of radii, on a variety of chamfers, continued Novak, “And it’s non-destructive.”

He elaborated, “For knicks and dents on blade edges or other difficult surfaces, we have a custom little tool that gets the optical system to the perfect focus. It can slide along, you can see a bright field image of the part, and it's colored green because we were in good focus and ready for the measurement.”

Novak proceeded, “Then down below, we have our actual measurement, showing a trace across the three-dimensional result where we can do the depth and the width of a dent on a blade edge.”

How has upgraded metrology benefitted aviation organizations?

Novak noted, “We have companies who, by implementing better metrology, have improved yields by more than 40%, reduced scrap and rework by more than 30% and dramatically reduced their test and measurement time so they get feedback instantly on their production lines.”

Showcasing the practicality of these products, Novak noted that people are typically trained very rapidly on the devices, often able to start taking measurements in under an hour.

He also highlighted how the practicality of enhanced metrology systems benefits aviation companies.

“Fast, handheld defect and geometry metrology provides a really rapid return on investment,” Novak said.

He continued, “Typically, in aviation, people tell us it's days to weeks because of the high value of parts, the high cost of failure, the high cost of labor when you are taking time doing measurements instead of actually repairing parts or rebuilding engines, and you can do in situ measurements.”

“A lot of times you can avoid disassembly, reassembly associated with inspection. You can look at it and only take it apart if it looks problematic,” noted Novak.

“And as you get into automation, some of the time savings become astronomical where people measuring, 40+, sometimes 100+different edge break or radii features that can take them hours to days. And in an automated system, you can bring that down to a few 10s of minutes,” he shared.