Speedcargo and Güdel Introduce Air Cargo Automation System for ULD Palletizing

Speedcargo, a tech start-up that offers AI and robotics solutions for air cargo in partnership with Güdel, a manufacturer of high-precision machine components and a provider of sophisticated automation solutions announce the world’s first fully automated robotic freight handling solution for air freight.

The new robotic system is expected to change the way air freight ground handlers store and move cargo at airports around the world. This robotic system is capable of handling cargo of a variety of sizes and weights, even odd-shaped cargo.

“As wages rise and labor shortages worsen, air freight handling will become increasingly automated. Our partnership with Speedcargo allows us to take advantage of the potential of pick-and-place applications when combined with artificial intelligence,” said Matthias Vogelsanger, CTO Güdel Group,

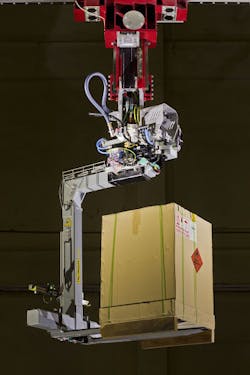

The system will improve three key ground handling operations by combining Güdel's advanced gantry robots and decades of intralogistics automation expertise with Speedcargo's advanced computer vision, optimization and intelligent robotics software.

First, the system improves cargo acceptance by creating express automated lanes with a seamless integrated process for weight, dimension and x-ray checks. This enables continuous cargo throughput at the acceptance gates and ready-for-carriage cargo to be moved to the buffer zone.

Secondly, the system allows for an automated buffer for storage and retrieval. Accepted cargo will be intelligently and efficiently stored and managed to enable precise and fast retrieval for a flexible and optimized ULD build-up. The system allows storage space to be managed dynamically, allowing the warehouse to be used to its full capacity.

Thirdly, the system automates ULD build-up. A.I. optimized ULD build-up plans are automatically executed using precision gantry robots while a centralized control system ensures that the cargo is fed to the palletizing robot in an optimized sequence that results in a fast, reliable and secure build-up. The system is also equipped with a range of sophisticated grippers and sensors to ensure that high-mix cargo is handled with a very high degree of safety and reliability.

Automated cargo handling solutions will address some of the key challenges faced by the industry around labor constraints due to demographic trends.

There is a dwindling number of trained and experienced cargo handlers. This trend has been accelerated by the COVID pandemic and ongoing retirements. New entrants to the workforce are less willing to do labor-intensive jobs, which involve both mundane tasks and hazardous heavy lifting. Robotic technologies and automation will make air cargo handling attractive to the next generation by upskilling the workforce and creating an environment that focuses on managing and controlling digital systems.

Automation also addresses space constraints. Increased cargo volumes are continuously putting pressure on warehouses, increasing demands on space and impacting handling safety and quality. Automation will not only increase cargo throughput but also save space and maximize the utility of existing infrastructure.

Lastly, automation establishes consistency and safety in quality handling. The existing handling process depends on trained and experienced handlers on the ground. With processes that rely on human labor, errors and delays are inevitable, especially with a fluctuating labor force and space constraints. Automating the cargo handling process will ensure consistent, safe, and quality handling with continuous 24x7x365 operations.

“Automation addresses key issues the air cargo industry is facing now and it will become a foundational building block for future airfreight operations,” said Dr. Krishna Kumar Nallur, CEO Speedcargo.