How to Prepare Fall Protection Crews for the Winter Weather

The U.S. Bureau of Labor Statistics (BLS) reports approximately 40,000 workplace injuries are directly related to snow sleet, or ice. In addition, approximately 450,000 falls occur in the workplace each year, with more than 1,000 resulting in fatalities.

While the importance of fall protection will not waver in any weather, winter weather can increase the risk of slips, trips and falls.

The winter weather can affect workers in ways unanticipated in months with clearer weather. Increased precipitation will make surfaces slippery and increase the chances of a fall, and harnesses may not fit properly over bulky outerwear.

Furthermore, organizations can capitalize on the desire to stay warm indoors to conduct training sessions and reinforce equipment inspection requirements.

Increased Precipitation

It’s important for workers not to become complacent with typical work conditions once winter storms bring unfavorable weather. Workers at height have an increased chance of slipping due to icy conditions brought by rain, snow or hail. Ideally, aircraft maintenance shops already have overhead anchorages installed over service bays to protect mechanics while working inside, and falls can be protected.

Maintenance repairs that must happen outdoors will have difficulty staying balanced while working on top of wet or frozen aircraft, and there is unlikely an overhead structure nearby to provide an anchor exactly where the aircraft is positioned.

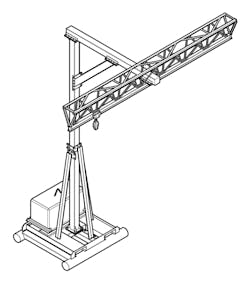

In these circumstances, temporary overhead anchorage posts (see Graphic A) can be moved anywhere a truck or forklift can drive and can provide workers with overhead fall protection anywhere on the airfield.

Graphic A

Harness Fit

Fall protection harnesses must be worn above all other outerwear and must fit properly when users increase layers to stay warm. If a worker’s harness is too small and cannot buckle over their winterwear, they would need to be supplied with a larger harness before performing any work at heights.

Hosting a “winter harness fitting” event can be a way to retrain crews on proper harness fit techniques and remind workers about the importance of always wearing their fall protection.

Proper harness fit is one of the most essential components to mitigating injury during a fall incident. During a fall, the harness will orient the victim upright during their fall. Suppose a harness is not adjusted properly (specifically, it is too loose) during this process.

In that case, the user risks being ejected from the harness, or the leg straps will eventually come together and put significant pressure on the user’s groin area, likely causing injury. Leg straps are designed to remain stationary on the thigh but will not stay in place unless tightened properly. One method to check leg strap tightness is to have enough slack to fit a flat palm under the leg strap, but not a fist.

Equipment Inspections

OSHA requires two types of inspections of all fall protection equipment: pre-use and annual inspections.

The pre-use inspection must be performed by users each time they use their fall protection gear and inspect for any physical defects that could affect performance during a fall.

Also, users must verify that the manufacturer’s label is still intact and that the harness has not experienced a fall. If a harness fails inspection for any reason, users must turn in the equipment and receive replacement equipment before accomplishing their tasks at-height.

All pieces of fall protection equipment must be inspected on an annual basis by the organization’s Competent Person. For logistical reasons, most organizations perform these inspections in the first quarter of the year. Each inspection must be thoroughly documented for the lift of the equipment. Failed equipment must be discarded & destroyed.

Employees should be trained in best practices for the maintenance and storage of the equipment to maintain its performance quality and increase its longevity.

Further Training Opportunities

Conducting indoor training sessions will likely be welcomed by crews during winter months, and organizations would be wise to spend that time retraining employees.

For example, if high failure rates are observed during annual equipment inspections, it could be due to a lack of pre-use inspections from the workers. Performing pre-use inspections together as a crew for a few days in a row can help form good habits and identify gaps in fall protection knowledge amongst users.

Organizations must get creative when it comes to increasing awareness and encouraging users to comply with fall protection policies.

For example, safety departments can encourage workers to make New Year’s Resolutions to help improve the facility’s fall protection. Fall protection resolutions can be quite productive, such as setting goals about discovering unidentified fall hazards, days spent without a fall incident or performing pre-use inspections.

This exercise or similar ones effectively keep fall protection at the top of crews' minds and helps foster a stronger safety culture. When safety is brought up frequently, it becomes less taboo, and workers continue to become invested in improving the safety of their shared environment.

Conclusion

Winter weather can increase the risk of falls but can also provide organizations the opportunity to improve systems and bolster fall protection programs.

If outdoor work must be performed at heights during unfavorable weather, planning ahead to provide the proper fall protection is essential to protecting the workers involved. Companies like Diversified Fall Protection have experience designing systems to protect workers from the worst-case scenarios and can help raise awareness with crews through continuing education and earned expertise.

Protecting workers from falling is a priority throughout all the seasons. But winter is coming, and the time to prepare for fall hazards is now.

About the Author

Philip Jacklin

Philip Jacklin is continuing education program manager for Diversified Fall Protection. He is an AIA continuing ed provider, QSSP certified, OSHA-30 trained and has been a partner to the fall protection industry since 2018. Jacklin has a background in worker advocacy, team leadership and fostering camaraderie among peers. He enjoys playing music, writing and spending time in the sunshine with his family in Virginia Beach, VA.