How airlines Can Turn the Actual Off-Block Time (AOBT) Into Profit

The Actual Off-Block Time (AOBT) is one of the most important milestones during a turnaround / flight. For many airlines, the AOBT marks the moment from which point onwards aircraft crews get paid. In practice, this milestone is often artificially fabricated to ‘put the crew on the clock’ while the flight is not yet leaving.

Over a period of 4 months, Assaia analyzed and compared the current AOBT obtained from aircraft sensor data via ACARS and the actual AOBT recorded by the Assaia’s Turnaround Control system at one of the largest US airports and found out that the average AOBT inaccuracy for all flights turned out to be as many as 180 seconds.

Given the fact that crews in some areas of the world start to get paid from AOBT onwards, the fabrication of this milestone at the incorrect moment is a breach of procedure that has a direct negative cost effect for airlines.

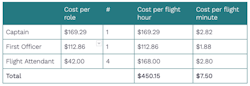

Table 1 shows the average cost for a crew across all aircraft types departing from the analyzed US airport. Based on these costs, the airlines’ benefit from switching to the Assaia Turnaround Control system generated AOBT timestamp is $23 per flight or more than $4.5 million per year.

Beyond this direct, negative financial impact, inaccurate AOBTs also result in suboptimal planning of airline and airport resources because it is based on false data. This leads to more operational inefficiencies and higher operational costs.

As airlines are emerging from almost two years of COVID crisis, it is crucial to focus on cost control and return to profitability. The AOBT fabrication negatively impacts these goals and furthermore might create a competitive disadvantage for airlines who do not control these practices.

Even though efforts like Airport Collaborative Decision Making (A-CDM) have been undertaken to address this matter and have already had a great positive impact, at airports using A-CDM principles, still many data points are manually generated or sensitive to human tampering. The Assaia’s Turnaround Control system on the other hand operates entirely automatically, no human intervention is required or possible. This implies that the system is impartial, objective and ultimately just reports what is happening at the gate making the fabrication impossible and saving airlines costs.

Read the full case study here.