The Accelerating Danger of Diesel Exhaust Fluid Contamination

Last May, two Cessna Citation 550 twinjets on air ambulance missions received fuel at a Southwest Florida airport that had been contaminated with diesel exhaust fluid, or DEF. While the two jets experienced engine failure, fortunately both landed safely. This marked the third time in 18 months that DEF has contaminated the fuel supply of a jet fuel truck and caused multiple-inflight aircraft engine failures.

DEF is a clear urea- and water-based fluid used in the emission reduction systems of modern diesel-engine vehicles as required by federal environmental mandates. When mistakenly added to jet fuel, it may trigger the formation of crystals that plug fuel filters and damage other engine components – potentially causing engine shutdowns. DEF is not an additive, but is stored in a specialized tank on the chassis of diesel engine vehicles and then injected into the engine exhaust to help reduce noxious emissions.

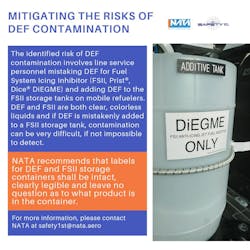

Details from previous jet fuel contamination incidents find the greatest risk in line service personnel mistaking DEF for Fuel System Icing Inhibitor (FSII). Since both are clear and colorless liquids, it is nearly impossible to detect if DEF is mistakenly added to a FSII storage tank. While none of the recorded DEF contamination incidents have resulted in an aircraft crash or fatalities, they reveal the urgency of developing procedures to take preventive action.

Recognizing that the introduction of DEF into an aircraft fuel system is not an isolated incident and poses serious safety risks, the Federal Aviation Administration (FAA) has addressed the problem in a special airworthiness information bulletin (SAIB HQ-18-28) and safety alert for operators (SAFO 18015). In addition, the National Air Transportation Association (NATA) offers DEF Contamination Prevention training course through its Safety 1st Supplemental Safety Training Program free of charge to those, particularly employees of fixed-base operators (FBOs) and other fuel providers, who can help prevent future incidents. NATA offers the following best practices to reduce the risk of aircraft misfueling with DEF.

Storage of Aviation Fuel Additives

- DEF and other fluids, oils and chemicals shall be stored in a separate location from FSII (FSII, Prist, Dice, DiEGME) and other aviation fuel additives.

- Locks for DEF and other fluids, oils and chemical storage areas shall be keyed differently than for areas containing FSII and other aviation fuel additive.

- Keys for locks shall be labeled and kept on separate key rings.

Fluid Handling

- Only approved and trained personnel shall handle DEF or fill equipment DEF tanks. All transfers of DEF shall be recorded in a log including date, time, transfer to/from and the name of individual completing the transfer.

- Only approved and trained personnel shall handle FSII or fill jet fuel refueling equipment FSII tanks. All transfers of FSII shall be recorded in a log including date, time, transfer to/from and the name of individual completing the transfer.

Procurement and Labeling

- DEF should be purchased in quantities that differ from FSII (i.e., 2.5-gallon containers vs. 55-gallon drums).

- Labels for DEF and FSII storage containers shall be intact, clearly legible and leave no question as to what product is in the container.

- All equipment DEF tanks shall be labeled “DEF ONLY.”

- Refillable FSII tanks on jet fuel refueling equipment shall be labeled “FSII ONLY” or” DiEGME ONLY.” Where replaceable 5-gallon FSII tanks are used, the manufacturer’s label shall be intact and clearly legible.

- Any equipment (containers, funnels, etc.) used to transfer DEF or FSII shall be clearly labeled and “product dedicated,” meaning that DEF transfer equipment shall only be used with DEF and FSII transfer equipment shall only be used with FSII.

Staff Training

- Initial and recurrent training for all staff shall include the purposes of and differences between FSII and DEF (including their different storage locations and package labeling) and the dangers of aviation fuel contamination with DEF.

- In addition to the above, initial and recurrent training for individuals handling DEF and or FSII shall include DEF fill points on all equipment requiring DEF, FSII fill points for jet fuel mobile refuelers and other refueling equipment as applicable and the use of clearly labeled, dedicated equipment when transferring DEF or FSII.

- All staff shall follow the personal protective equipment recommendations found in the Safety Data Sheets for FSII, DEF and other fluids and chemicals.

NATA is also working closely with government and industry stakeholders – including the Aircraft Pilots and Owners Association, National Business Aviation Association and General Aviation Manufacturers Association – to develop additional resources to mitigate DEF contamination incidents at airports.

If you believe that jet fuel has been contaminated with DEF, the FAA recommends that owners and operators first contact their aircraft, engine and APU OEMs to determine the appropriate inspections and maintenance actions to remove urea-based crystalline deposits from the fuel system. This action may include removing and replacing fuel system parts of components affected by exposure to these deposits. Second, report to the FAA any service difficulties, fuel system repairs and rule system inspection results related to this work. Third, discard any jet fuel that has been removed from an affected aircraft and ensure it is not used on other aircraft or vehicles. Finally, discuss with your local fueling providers what protocols are in place to prevent and test for jet fuel contamination.

Clearly, DEF contamination poses a very real and significant threat to aircraft safety. Similar to the historical success of proper training for other fuel-related procedures that NATA has undertaken, effective mitigation measures must be swiftly enacted. In order to best assure that fueling is completed based on the highest level of safety standards, FBOs and aircraft operators must ensure their employees are properly trained and that proper protocols to prevent DEF contamination are stringently observed.

Curt Castagna, president and CEO of Aeroplex/Aerolease Group, is a member of the Los Angeles County Airport Commission, president of the Van Nuys and Long Beach Airport Associations, and board chair of the National Air Transportation Association. A certified private and instrument-rated pilot, he has instructed courses in aviation administration at Cal State Los Angeles for over two decades.

About the Author

Curt Castagna

President and CEO

Curt Castagna, President/CEO of Ascension Group Partners, serves as president and CEO of the National Air Transportation Association, member and past chair of the Los Angeles County Airport Commission, and president of the Van Nuys and Long Beach airport associations. A certified private, seaplane and instrument-rated pilot, he continues to instruct courses in aviation administration at Cypress Community College and Cal State Los Angeles.