Improving Surface Defect Measurement: Solutions and Case Studies

4D Technology today announced the latest event in its continuing Surface Metrology Webinars series.

The "Improving Surface Defect Measurement: Solutions and Case Studies" webinar will be held on Tuesday, July 18, 2017, 12:00 PM - 1:00 PM Eastern Standard Time (16:00 GMT).

Register for the webinar at https://attendee.gotowebinar.com/register/611815932310945537.

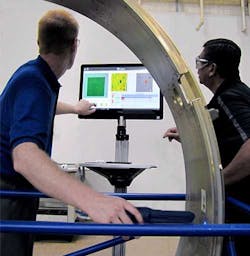

The 4D InSpec is the first handheld surface gauge that measures machined surface defects and features, with micrometerlevel resolution. The instrument is used here to measure defects on a large aircraft engine component. A high resolution version of this image is enclosed. Image is used Courtesy of StandardAero.

Accurate measurement of surface defects is essential to the long life and performance of precision components for aerospace, automotive, and other applications.

The challenge facing inspectors is how to quantify pits, scratches, bumps, etc., with sufficient resolution, coverage and speed to satisfy customer requirements—particularly on complex surfaces or on large components.

This webinar will cover the challenges involved in making accurate surface defect measurements on precision machined surfaces. Kevin Harding, President of Optical Metrology Solutions (recently retired as a General Electric Research Principal Scientist), will discuss the strengths and shortcomings of common measurement techniques, ranging from assessing surface defects with a “calibrated fingernail” to employing high-end 3D surface profilers.

Dr. Erik Novak of 4D Technology Corporation will present the 4D InSpec® Surface Gauge, the first handheld, precision instrument for non-contact, 3D measurement of surface features and defects. Developed in conjunction with major aerospace and precision machining companies, the 4D InSpec measures defects from 4D Technology Corp., 3280 E. Hemisphere Loop, Suite 146 Tucson, Arizona 85706 0.1 to 100 mils deep, even in difficult part locations, with measurement times of a few seconds and instant results and reporting.

Examples from manufacturing and repair/rework facilities will be presented, in which the new gauge has been used to dramatically reduce measurement cycle time, decrease the rate of rework due to false-positive measurements, and improve the traceability and reliability of measurement results.

A recording of the webinar will be made available to all registrants shortly after the event.

4D Technology, the 4D Technology logo, and 4D InSpec are trademarks of 4D Technology Corporation. All rights reserved. 4D InSpec is covered by U.S. Patents 67230717, 7777895 and 7489408. Other patents pending.