Long waiting times make airports look bad and upset passengers. Even worse, long queues make airports lose money. According to the study “Rise to Challenge – the risks and opportunities of digitization for airports” from the renowned consultancy Roland Berger, a five-minute delay for 25 percent of passengers at the security checkpoint could induce a drop in retail sales of two to three percent. People that wait more, spend less.

Conversely, cutting average security waiting time by one minute may entail higher revenues of USD 1.5 to 2.3 million, as Passenger Flow Terminal reported on a case study of passenger flows conducted at Toronto Pearson International Airport in September 2016. This correlation seems also to apply to smaller and mid-size airports. Federico Cabrera, CCO at Aeropuerto Internacional de Carrasco in Uruguay’s capital Montevideo confirms: “Shortly after we had installed a 3D stereo vision based system to measure waiting times, we could optimize staff planning and hence reduce waiting times at security checkpoint. This led to a remarkable increase in retail sales of up to 10’000 $ in just three hours”.

A Broad Range of Technological Options

The fundament to tackle waiting times, leverage customer satisfaction and keep up with the fierce competition, is an accurate and reliable system to measure waiting times. In recent years, the array of technologies to address the issue has expanded along with the awareness of the problem. Many different names are used to describe technologies to measure waiting times, such as queue measurement systems, passenger flow analysis and people flow monitoring. Typically, all the available technologies count people in the relevant area (e.g. at security checkpoint or even in check-in/ticketing areas) and measure their dwell times, based on which an algorithm calculates the resulting waiting times. The differences between the various approaches lie in cost, installation and maintenance efforts, accuracy, reliability, and scalability:

- Wi-Fi/Bluetooth: Depending on passengers having Wi-Fi/Bluetooth enabled on their smartphones or other devices, these features can be used to estimate waiting times. Usually, sample rates of such systems are rather low, since only a fraction of the enabled devices can be detected.

- Infrared: At the start and end of a designated queuing area passenger are counted when crossing a threshold and thereby breaking a beam of light from a sensor. The waiting time is measured based on the number of passenger in between.

- Thermal cameras: Thermal cameras measure waiting times based on heat emitted by passengers. Since thermal cameras detect heat in general, he measurements are prone to error by other sources of heat.

- Conventional video based systems: A specific software processes the video output from conventional cameras and calculates the waiting time. Using already existing cameras, installation is simple but can interfere with other video based applications and increase the total lifetime costs considerably due to the required network and computing capacities. As with all technologies based on two-dimensional images (monovision), bright sunlight, shadows, and other external influences negatively affect the accuracy.

- 2D sensors: Typically mounted on the ceiling, 2D sensors have a built-in camera (monovision). The sensor differs from regular CCTV cameras by directly processing the image on the sensor itself to count people and measure the dwell time. Thus, network load and required server capacity is significantly reduced. An additional software combines various sensors to cover large areas and to measure the waiting time. As with all monovision technologies, light changes, shadows, and other external influences negatively affect the accuracy.

- 3D sensors: Typically mounted on the ceiling, 3D sensors have two inbuilt cameras (stereovision) to calculate a 3D depth image. A software on the sensor performs the image processing directly on the sensor to count people and measure the dwell time. An additional software combines various sensors to cover large areas and to measure the waiting time. 3D sensors are much more robust against light changes, shadows etc. than 2D cameras.

How to Pick The Most Suitable Technology?

So, there is a long list of technologies and suppliers for airports to choose a from. How and based on which criteria should an airport keen to measure waiting times and related key performance indicators (KPIs) pick the most suitable solution for the company’s aims? Table 1 compares the different technologies regarding six decisive factors

Basically, the level of required sophistication determines the technology. A rather small, only seasonally busy airport may get by with a rather simple, easy-to-install technology such as Wi-Fi/Bluetooth, infrared sensors, or thermal cameras. Waiting times measured with Wi-Fi/ Bluetooth technology are more kind of an estimate as opposed to a measurement, since they only detect enabled devices. There are new technologies such as “MAC randomization” that aim at preventing devices from being detected, which further question this approach.

Large, steadily busy international airports ought to opt for a more high-tech, optical solution. This assumption is in line with some trends that are likely to dominate the airport industry in the next 20 years. According to the International Airport Review the passenger of tomorrow expects an impeccable expectation management via real-time data through all channels. Additionally, the International Air Transport Association (IATA) expects 7.2 billion passengers to travel in 2035. This equals almost a doubling of the 3.8 billion air travelers in 2016, urging airports to further optimize capacity utilization or add new capacities.

Accuracy Gap Between Different Optical Systems

Considering the major challenges for airports, optical systems seem to have an edge over other technologies. Only optical solutions enable users to constantly receive real-time data along with live views of the relevant areas. But not every optical technology meets the expectations to the same degree: conventional video camera based approaches arise from the desire to combine existing video cameras (CCTV) with video analytics software and hence avoid investments in new equipment. But they fall short of the required accuracy and reliability, as the image processing in monovision, i.e. one camera, is limited per se. For example, if a passenger stands closely in front of another passenger form the camera’s perspective, only one person instead of two are counted and the waiting time is distorted. Furthermore, the image processing occurs on external devices and requires both considerable network and computing capacity, which increases total lifetime costs significantly. 2D sensors enable direct image processing, but feature the same accuracy/ reliability short-comings attributed to monovision per se and only satisfy the requirements in well lighted environments. All in all, systems based on 3D sensors deliver the most complete package, when it comes to measuring waiting times at highly frequented and complex airport sites with demanding passengers.

A 3D System in Action

A glimpse at a practical example sheds light on the question why 3D sensors based system achieve the highest level of accuracy, reliability, scalability while keeping the total lifetime cost low. Switzerland based Xovis combines interconnected 3D sensors and software solutions to measure and predict KPIs such as passenger counts, dwell time, queue length, desk/ lane activity, waiting time, process time and passenger throughput in large areas.

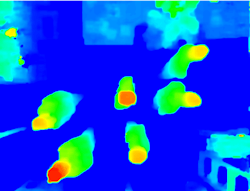

When entering the covered area, every passenger is counted, tracked and allocated to a queue according to an “automated queue detection” algorithm. Passengers that are not queuing, are excluded from the measurements (white dots in img 3). Each of the deployed devices combines two image sensors to see three-dimensionally – very similar to the human eye; two “eyes” identify pixels that correspond to the same point in an observed scene to determine the 3D position of this point via triangulation.

3D sensors are independent from signal-emitting devices and highly robust against external influences, such as shadows, light changes and heat emissions. Numerous tests have substantiated the accuracy of the Xovis system measuring the desired KPIs.

A 3D Vision For The Future

Accurately measured waiting times are a powerful tool to optimize airport operation and ultimately increase customer satisfaction. As the Khaleej Times, Passenger Terminal Today and other media reported in May 2017 the third largest airport in the world, Dubai International Airport (DXB), has reduced waiting times by a remarkable 10 per cent during the first three months of 2017. Over 5000 operational staff members use the data, gathered by 530 Xovis 3D sensors and visualized by the Xovis software in a simple mobile application, to identify bottlenecks. In case the waiting time in a certain area exceeds a defined threshold, the team is alerted and can tackle the issue by sending more staff members and opening more counters.

"This automated system provides us with timelier and more accurate data more quickly than the manual system that was used previously. As a result, the operations team and other organizations that work across the airport now have a bird's eye view of bottlenecks, allowing them to better manage staffing levels and lanes, and improve the overall customer experience. We have more work to do in this area, but we are pleased with progress to date", says Frank McCrorie, Senior Vice President of Operations at DXB to the Khaleej Times.

Marc Rauch leads the recently founded Xovis office in Boston, MA. Prior to joining Xovis as Managing Director USA, Marc had worked more than ten years in various capacities for Xovis’ first customer, Zurich Airport. Founded in 2008, Switzerland based Xovis AG has evolved from a three-man start-up to a high-tech company with more than 80 employees. Firmly rooted in the airport business, the Xovis 3D sensors are also establishing as standard in other industries such as retail and security. The sophisticated data privacy concept ensures compliance with different regulations in different countries. The direct image processing keeps infrastructure costs at a low level. Today, more than 40 international airports count on Xovis to measure KPIs such as waiting times, process times and passenger throughput in order to tackle waiting times.