PW100 Turboprop Makes New Inroads in the Regional Airline Market

Pratt & Whitney Canada’s iconic PW100 turboprop engine family is continuing to gain altitude in the global regional aircraft market 30 years after its entry into service. P&WC continues to invest in product enhancements for the PW100 family and with over 6000 engines in service today, the PW100 will be powering regional turboprop aircraft for many years to come.

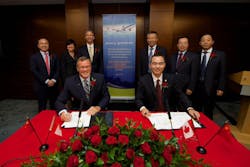

Transport Canada and the European Aviation Safety Agency (EASA) recently certified the PW127N for a new fleet of ATR 72-600 aircraft and AVIC Xi’an Aircraft Company of China selected the PW150C for its new MA700 regional turboprop aircraft.

“The PW150C win extends P&WC’s presence in China’s rapidly growing aviation industry,” confirms Richard Dussault, P&WC Vice President of Marketing. “It also reinforces the company’s long-standing relationship with AVIC.” The relationship dates back to the late 1980s when the PT6 engine was selected to power the Y12 utility aircraft. P&WC’s relationship with AVIC was also marked by a collaboration with Xi’an Aircraft Company in the development of the MA60/600 aircraft powered by the PW127J in the early 1990s.

P&WC’s PW150C turboprop engine leverages the success of the PW150A engine by providing increased performance and power reserve through the addition of a third-stage power turbine, a modified reduction gearbox to support the aircraft’s larger diameter propellers, and an enhanced low-pressure compressor. The enhancements in the engine and the high-efficiency propeller are customized to meet the specific needs of the MA700 to provide significant fuel burn economics for the new aircraft. “P&WC continues to look into how PW150C features can be implemented in the existing fleet,” adds Dussault.

The newly-certified PW127N engine builds on the success of the PW127M, which has accumulated over 10 million hours of operation, and offers enhanced performance in hot and high operating conditions, including a 4.5% thermal power increase for Maximum Take-Off ratings (MTO). Field conversions from the PW127M will be feasible with minor hardware modifications, such as Electronic Engine Control (EEC) & Data Collection Unit (DCU) software changes, new harness and trim plug, among others.

Says Dussault, “P&WC is continuously investing in the development of product enhancements to its PW127 family and expects to roll out additional hot end durability features in 2015 that will increase the time-on-wing performance of the PW127M and PW127N engines.” Some additional fuel burn benefits are also expected from these modifications to further bolster the competitiveness of the regional turboprop.

P&WC is also currently investing in technology for the next-generation regional turboprop (NGRT), which will offer 20% better fuel burn and 30% lower maintenance costs with the efficiency and flexibility of a fully integrated propulsion system. It has launched a detailed design of an all-new NGRT and is nearing completion of Phase 2 of compressor testing as part of a technology demonstrator program. The NGRT will deliver in the range of 5,000 to 7,000 shp as well as economic and environmental benefits that will sustain the regional turboprop’s competitive advantage for airlines serving short-haul, high frequency routes.