Neutron Imaging: The Newest NDT Method in Aerospace

Nondestructive testing, the testing and evaluation of materials and components for potential discrepancies without harming their integrity and serviceability, is an essential element of maintenance, repair and overhaul (MRO) and quality assurance in the aerospace industry. Regular NDT inspections ensure the safety of the full lifecycles of aircraft and spacecraft by detecting any defects in the equipment.

The American Society for Nondestructive Testing (ASNT), the largest technical society of NDT personnel, recognizes six most used methods, including radiographic testing (RT) and ultrasonic testing (UT), as well as 10 additional specialized methods. However, as technology advances and materials become increasingly complex, cutting-edge NDT methods have emerged as alternative options for inspectors to use when further examination is required. One of these specialized methods gaining traction among inspectors, especially in aerospace, is neutron imaging.

N-ray vs. X-ray: What’s the Difference?

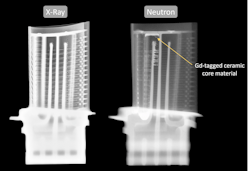

Introduced as a viable NDT method in the 1950s, neutron imaging—or neutron radiography (N-ray) and tomography—is similar to RT or X-ray in that it uses penetrating radiation to create visuals of the internal structure of objects. RT, also known as industrial radiography, is a common NDT method that uses ionizing electromagnetic radiation of X-rays or gamma rays to view the internal structure of a component.

Although it's conducted in a manner similar to traditional RT, N-ray uses a neutron source instead of an X-ray source to penetrate high-density materials. The primary difference between these two methods is that where X-rays interact with the electrons of a component, neutrons interact with the protons and neutrons of the atom’s nucleus, providing a very different result.

Neutron Technology without Nuclear Reactors

Traditionally, N-ray uses a neutron beam for imaging, which requires a nuclear reactor. This is expensive, highly regulated and unavailable to most companies. Additionally, as more nuclear reactors age and are decommissioned, access to neutron power sources becomes more difficult.

However, companies have begun designing alternative technologies like compact fission reactors and high-flux neutron generators that can be applied for neutron imaging, reducing the need for a nuclear reactor. The development of alternative power sources like linear accelerators also allows N-ray to become an increasingly common and cost-effective testing method for inspectors across industry sectors.

In recent years, alternative nuclear power sources like neutron generators have become much stronger and more attainable. A few nuclear technology companies are focusing their efforts on enhancing their non-reactor commercial neutron imaging services. Phoenix Neutron Imaging, a Wisconsin-based nuclear technology company, began operating its non-reactor neutron imaging facility commercially in 2020 and has since maintained high-quality N-ray services in compliance with ASTM standards and aerospace manufacturing regulations.

The Growing Demand for Specialized Technicians

With advanced technology and growing access to neutron power sources, inspectors are now better equipped to perform neutron imaging for NDT more often. While N-ray testing is becoming more accessible thanks to alternative neutron sources, the aerospace industry still faces a shortage of NDT technicians certified in this specialized method.

As an emerging NDT method in aerospace, neutron imaging is used daily to test critical aerospace components, like high-pressure turbine blades, to catch critical flaws. From failure analysis and weld testing to quality assurance, this testing method is becoming more popular among NDT professionals. Its emergence as a more prevalent NDT method is partially due to better accessibility.

Safeguarding the Skies Through Advanced Inspection

Aerospace vehicles, from commercial airplanes to rockets, are designed to sustain performance in the face of high speeds and atmospheric conditions. As a crucial part of aircraft manufacturing and aircraft maintenance and repair processes, NDT technicians inspect materials at several stages to maintain safe and reliable operations.

With increasing dependence on the aerospace industry due to its vital role in national security and ever-increasing passenger transportation, there is a growing demand for NDT inspectors who are trained in specialized methods and modern techniques and are able to evaluate complex components of state-of-the-art aircraft and spacecraft.

Most NDT technicians are certified through technical organizations like the American Society for Nondestructive Testing (ASNT) or from their employer. Currently, inspectors can obtain certification recognized by most industry operators from ASNT in a variety of NDT methods for Level II and Level III.

RT, which uses X-rays in inspections, is one of the established courses offered by ASNT. NDT technicians who are adept at conducting neutron imaging today are often trained in internal programs from their employers. However, employer-based programs do not guarantee the same distinction that certification through organizations, like ASNT, can provide. As this testing method becomes more prominent, expanding formal neutron radiography training classes and certification will address this issue.

The Future of Neutron Imaging

Demand for N-ray is growing. As more qualified inspectors enter the field, they will expand the use of neutron imaging as a valuable testing method. Advancing aircraft and spacecraft components—and the increasingly complex materials used to build them—requires modern tools like neutron imaging to make inspections more efficient, more effective and more capable of protecting every person who zooms through our atmosphere.

About the Author

Greg Weaver

Greg Weaver, is ASNT and NAS-410 Level III with ASNT certifications in Radiography, Liquid Penetrant Testing as well as the addition of Ultrasonic Testing for NAS-410. Greg has over 25 years of quality and inspection experience in the aerospace, power generation and automotive industries.