We have all heard the expression – “If everything is important then nothing is.” That expression is often used in business or psychology circles. However, it is difficult to apply the expression to aviation maintenance where, it seems that everything IS important!

Considering Human Factors, we can pick and choose regarding matters of greatest importance. For example, a good night’s sleep probably trumps a morning-time double espresso. Clear written communication beats a verbal message. However, in maintenance, is using the correct oil as important as proper safety wire on the oil filter? Either can lead to improper lubrication and/or oil starvation. Both actions are important. As we search to determine what maintenance actions are of greatest importance, we usually conclude that all maintenance is important for safety. Hence, “If everything is important then what is most important?”

In this article I offer examples where either flight controls or locking devices were the primary contributing factors to an event/accident. As you might expect, I conclude that it was human error, during maintenance, that caused the events. Therefore, I contend that it is the human factors that are of utmost important. If we make human factors important then the importance of every maintenance operation will follow accordingly.

Each event discussed herein begs the questions, how could this happen, and what is of utmost importance? Based on the level of seriousness, injury, or fatality of the incident the investigation will have increasing levels of identification of the contributing factors. Lacking some details, I offer conjectures regarding probable causation. The examples below range from General Aviation to Air Carrier maintenance.

Small Fixed Wing: Loose throttle cable on a Cessna 182T Skylane, 2021

While in cruise flight the engine went to full throttle and then to idle. The pilot had no control of the throttle from the cockpit. A successful forced landing left the aircraft intact, with obvious evidence. The nut that secured the throttle cable to the throttle body was loose, with no cotter pin installed. What could have caused this situation? Because the outcome was minimal there is no detailed event report.

Here are some possible reasons: non-licensed owner maintenance; lack of training/experience of AMT; failure to adhere to AC 43.13-1B Chapter 7. Aircraft Hardware, Control Cables, and Turnbuckles; complacency with respect to engine controls criticality, and/or lack of second inspection. It could have been issues like stress; complacency; preoccupation with other matters; rush to completion; or personal fitness for duty. These familiar factors can apply to this event or to most of the events below.

Helicopter Tour: Flight Control Disconnect on AeroStar 350, 2011

Any observer of maintenance flight safety and human factors is likely familiar with the Sundance helicopter crash in the Grand Canyon (NTSB, 2013). The day following a change to the rotor blade control servo, the craft encountered fatal loss of control, and impact into a canyon wall. There were five fatalities. The control to the servo was not properly attached and became disconnected during a routine tour flight.

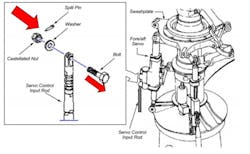

Figure 1. Main Rotor Servo Input Rod and Locking Devices

Reuse of a self-locking nut and absence of a locking pin were the likely cause, see Figure 1. The NTSB cited failure to have and follow maintenance procedures; fatigue-related fitness for duty of the AMT and inspector; and the importance of human factors training for everyone in the organization. Read the accident report (NTSB/AAR-13/01).

Emergency Rescue Helicopter: Flight Control Disconnect on Airbus Dauphin, 2020

This event had similarities to the helicopter event above (German Federal Bureau of Accident Investigation, 2020). The emergency rescue helicopter encountered a significant rotor control linkage disconnect at lift-off. The craft rapidly descended, about a meter, back to the runway with only minor damage to the tail rotor. Upon post-accident inspection a large bolt and castellated nut were found on the floor of gear case cabinet. The disconnect linkage is shown in Figure 2. The aircraft had flown nearly nine hours, after heavy maintenance, before the parts disconnected.

Figure 2. Disconnected Flight Control Linkage.

Like the Sundance helicopter, there was no cotter pin found. The found self-locking nut could be turned on to the bolt by hand. The mechanics/engineers/inspector that completed the work were highly experienced and recalled using proper locking techniques. However, careful laboratory inspection proved that the cotter pin was not used and the nylon in the locknut was worn out. Here is the list of contributing factors recommendations from the report:

- Maintenance work where the screw fitting involved was loosened and tightened again

- Use of a worn Nylon stop crown nut with insufficient friction torque

- Application of an insufficient torque of the crown nut

- Omission of a cotter pin protection of the crown nut

- Insufficient check of the work by the examiner

- Omitted check of the screw fitting of the flight controls during the 10-flighthour/ 7-day-inspection.

The excellent final report has extensive human factors discussion and is interesting reading.

Small Twin: Elevator Trim Tabs Installed Upside Down on Piper PA-31P Navajo, 2021

A Piper PA-31P Navajo, with just the post-maintenance airline captain/pilot/owner on board, took off from Myrtle Beach, South Carolina on May 2, 2021. It was the first flight after an annual inspection and painting of selected flight control surfaces.

Immediately after takeoff, the highly experienced airline captain/pilot/owner told the control tower that he was having control issues. Investigators immediately discovered that the elevator trim tabs were installed upside-down and backwards (Flight Global 9/11/21). The usual questions about maintenance procedural compliance, training/certification of mechanics and MRO, fitness for duty, and interference/rush by the owner are likely contributing factors. NTSB report is not published at press time of this article.

Commercial Carrier: Flight Control Reversal Portugal, Alverca do Ribatejo Air Base, November 2018

An Embraer 190 incident during which the aircraft departed with cross-rigged aileron cables, almost lead to the loss of the jet. The aircraft departed a Portuguese base after undergoing scheduled maintenance at an MRO facility. The maintenance also involved work on the aileron rigging.

"The cross-rigging of the ailerons left the crew struggling to control the jet’s attitude, notably in the roll axis. Such was the severity of the situation that, at one point, the pilots sought to head for the sea in order to ditch. Eventually, after considerable test-flying, they managed to regain a degree of control and eventually land” (Flight International, 2020). Figure 3 shows an animation of an extreme attitude during the initial flight.

Figure 3. Simulated Disposition of Aircraft During Initial Flight.

As part of the maintenance work, the E190’s aileron cables were disconnected to be re-routed and replaced. However, testing was delayed and then conducted by personnel without relevant experience The mechanics later revealed that they found the maintenance instructions difficult to follow resulting in the unrecognized mis-rigging.

The inquiry, conducted by Portuguese investigation authority GPIAAF, determined the improper aileron cable installation to be the probable cause of the incident, identifying lack of an effective safety-management system and inadequate independent procedures to detect maintenance escapes. In “plain language”, the untrained AMTs did not understand/follow procedures in a culture that permitted such activity. This improper maintenance activity was exacerbated by the flight crew that did not check operation of flight controls prior to takeoff. There was plenty of human error to go around but in this case the aeronautical skill of the flight crew prevented a fatal loss.

The Examples Continue

A quick web-search on terms like “flight control accidents” offers an extensive array of bad endings from flight and engine control maintenance. I especially recommend a link to Aerossurance (2019). That discussion offers additional examples with a focus on human factors.

Reviewing What’s Important

Well, this is the section of an article is where the writer must come up with brilliant conclusions and remedial actions! We can look at the five accidents above and a hundred more, just like them, to say that the familiar human-centered facts hold true. Maintenance workers must come to work physically and mentally ready to follow procedures, to communicate clearly, to speak up when training is needed, to address unclear instructions, to refuse to be rushed into poor decision-making or unairworthy work, and to value the importance of final inspection.

Work on flight and engine controls, on electrical systems/appliances, on flight surfaces, on powerplants, and on pressurization and cabin environment is all important. When it comes to maintenance the expression “If everything is import then nothing is important,” does not apply. I end by repeating that if you get the important human factors interventions in place then the other important maintenance activity will proceed safely.

Further Details:

Aerossurance (April 2019) FAA rules applied: So mis-rigged flying controls undetected. http://aerossurance.com/safety-management/faa-c172-misrigged-controls-hf/. German Federal Bureau of Accident Investigation (2020) https://www.bfu-web.de/EN/Publications/Investigation%20Report/2020/Report_20-0362-7X_AS365_St.Peter-Ording.pdf?__blob=publicationFile .

Flight International (7/2020), https://finreader.flightglobal.com/publications-dist/1263/7943/3135/43188/article.html and https://www.flightglobal.com/safety/control-check-routine-led-e190-upset-crew-to-miss-reversed-ailerons/139149.article and Control-check ‘routine’ led E190 upset crew to miss reversed ailerons.

Flight International (9/21). Mis-rigged trim tabs discovered after fatal Navajo crash in South Carolina. https://www.flightglobal.com/safety/mis-rigged-trim-tabs-discovered-after-fatal-navajo-crash-in-south-carolina/144039.article and https://aviation-safety.net/wikibase/262221.

NTSB (2013) Loss of Control, Sundance Helicopters, Inc. Eurocopter AS350-B2, N37SH, Near Las Vegas, Nevada December 7, 2011, Accident Report, NTSB/AAR-13/01. PB2013-103890.

““Dr. Bill” Johnson is a familiar name and face to many industry and government aviation audiences. Johnson has been an aviator for over 50 years. He is a pilot, mechanic, scientist/engineer, college professor, and senior executive during his career. That includes 16+ years as the FAA Chief Scientific and Technical Advisor for Human Factors.

Dr. Bill has delivered more than 400 Human Factors speeches and classes in over 50 countries. He has 500 + publications, videos, and other media that serve as the basis for human factors training throughout the world.

Recent significant awards include: The FAA “Charles E. Taylor Master Mechanic” (2020); The Flight Safety Foundation - Airbus “Human Factors in Aviation Safety Award” (2018), and the International Federation of Airworthiness “Sir Francis Whittle Award” (2017).

Starting in 2021 Johnson formed Drbillj.com LLC. In this new venture he continues to bring decades of human factors experience to aviators, worldwide.

About the Author

Dr. Bill Johnson

Chief Scientific and Technical Advisor Human Factors in Aviation Maintenance, FAA

““Dr. Bill” Johnson is a familiar name and face to many industry and government aviation audiences. Johnson has been an aviator for over 50 years. He is a pilot, mechanic, scientist/engineer, college professor, and senior executive during his career. That includes 16+ years as the FAA Chief Scientific and Technical Advisor for Human Factors.

Dr. Bill has delivered more than 400 Human Factors speeches and classes in over 50 countries. He has 500 + publications, videos, and other media that serve as the basis for human factors training throughout the world.

Recent significant awards include: The FAA “Charles E. Taylor Master Mechanic” (2020); The Flight Safety Foundation - Airbus “Human Factors in Aviation Safety Award” (2018), and the International Federation of Airworthiness “Sir Francis Whittle Award” (2017).

Starting in 2021 Johnson formed Drbillj.com LLC. In this new venture he continues to bring decades of human factors experience to aviators, worldwide.