AEM and TESTIA Pen CVM Sensor Installation Training Agreement

Canadian avionics and sensor manufacturer, Anodyne Electronics Manufacturing Corp. (AEM), and global non-destructive testing consultants and service provider, TESTIA, have signed a letter of intent for a new distribution arrangement to provide commercial airline operators and MROs installation training of its Comparative Vacuum Monitoring (CVM) airframe crack detection compliance sensors.

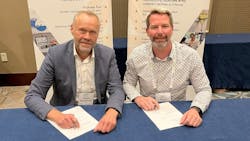

The non-binding letter of intent sets out the framework for the negotiation of a binding agreement, which will see TESTIA deliver a complete end-to-end installation training program and instruction to airline maintenance teams and third parties, adopting AEM’s airframe crack detection compliance sensor solution for non-destructive testing (NDT) inspections of the B737 Aft Pressure Bulkhead (APB). AEM and TESTIA signed the letter of intent at the Airlines for America Nondestructive Testing Forum (A4A NDT Forum) in Denver, CO.

Present for the signing of the letter of intent were Holger Speckmann, Managing Director of TESTIA GmbH, and Trevor Lynch-Staunton, AEM’s Chief Technical Officer, and lead Structural Health Monitoring Engineer.

While consideration and payment terms of the aforementioned letter of intent are still to be agreed, the binding agreement is expected to be signed within the next three months.

“Supporting AEM by providing training and installation services around the CVM technology, and being a reliable partner, fit into the future strategy of TESTIA as an end-to-end provider of Structural Health Monitoring solutions,” says Speckmann.

CVM is the first FAA certified, non-destructive, failsafe at-the-gate structural monitoring solution for achieving condition-based maintenance. The technology is already installed on 26 of Delta Air Lines’ 71 B737 aircraft and is expected to significantly reduce the time and labor maintenance crews spend monitoring and inspecting these airframes for cracks.

“In what used to take days in the hangar now takes minutes at the gate or on the overnight,” says Lynch-Staunton. “CVM will revolutionize structural health monitoring inspections and streamline maintenance program efficiencies by replacing costly inspections at heavy and out-of-sequence checks.”

“A CVM optimized MPD can restore thousands of flight hours back to the network across entire commercial fleets each year, he adds.”

CVM is currently approved by the FAA for use on the center wing box, front spar shear fitting, and the Intelsat (Gogo) Wi-Fi antenna inspections for select B737 aircraft, and on track for FAA approval of itsService Bulletin for the B737 APB application.