How to Maintain Cabin Combustion Heaters

Callout:

“Cabin heaters are like toilets. You only think of them when they don’t work.”

Anonymous

If nothing else, this past winter’s record-setting low temperatures served to remind everyone that cold is one of those weather conditions that you really can’t fly around. If you hit rain or turbulence you can deviate. Or if it’s hot, you can just keep climbing until you find cool air. But when it’s cold, it’s cold everywhere.

Fortunately, for those pilots who do operate in colder climates, cabin combustion heaters have an excellent history for safety, performance and reliability. That’s why it always surprises me when I hear an aircraft owner, or technician, say that cabin heaters are “dangerous.”

Yes, there’s a unit burning fuel in the aircraft, but they were designed with safety in mind and when properly maintained are one of the safest and most reliable systems in the aircraft.

Of course, while proper maintenance and operation is key to safety, some owners just don’t give these units the respect they deserve. As Harold (Hal) Haskins, Jr., owner of Harold Haskins Inc., a well-respected cabin heater repair facility put it: “Pilots don’t give a flip about the heater until they need it and nothing happens. They hardly ever give it a look during the preflight. They just expect it to work.”

Too true. Most pilots don’t give their systems a second thought. Yet, the heater’s excellent safety and overall performance record is exceptional and a tribute to the system’s original design.

In fact, that record is one reason most pilots and many technicians are caught by surprise when the heater doesn’t heat. Even saying the “heater doesn’t heat” is often technically incorrect.

“Most of the time it’s the combustion air blower motor that quits and not the heater,” Haskins says. “The heater chamber has a combustion air pressure switch and when it doesn’t sense the air pressure coming from the blower motor it will go open. It’s a safety device.”

“The switch actually closes when it senses the air pressure. That means it’s okay to run, so the switch allows the fuel and ignition to function,” he says. “If the blower motor fails, then the switch will open and cut-off the fuel and ignition on the heater.”

The sensing switch Haskins mentions is just one of many safety sensors and valves in a combustion heater system. If any of these devices fail and/or sense a malfunction within the area they protect, the heater will not function.

Aside from the sensors, units and motor, Haskins says another point of failure could be the unit’s igniter. “If that fails there is no spark to ignite the fuel. The clue that there is an ignition problem, is a little bit of raw fuel will run out of the drain or exhaust stack of the heater within two or three minutes of turning the system on,” he says. “That, and there’s no heat…”

Signs of fuel stains around these areas are one of the first things you need to look for during aircraft inspections or when troubleshooting a heater problem.

Keeping a combustion cabin heater healthy

While it may not seem like there’s much you as the technician or the aircraft’s pilot/owner can do to increase a heater’s lifespan, the fact is there are some pretty effective and proactive steps you can take.

For example, during your routine checks, inspect the ventilating and combustion air inlets, the exhaust outlet and fuel drain for obstructions. Also, inspect the exhaust area for signs of soot buildup – that could indicate improper fuel mixture to the burner.

You should periodically inspect all the electrical connections and wiring. The unit’s spark plug should be removed for servicing and inspection of the electrode. The heater’s fuel system should be pressure checked and any filters should be cleaned.

A pressure decay test of the combustion tube is also recommended every 500 hours. The purpose of the combustion tube is to contain the primary heat source (flame) and protect the rest of the chamber from flame erosion. Along with insulating the flame, it also protects critical weld seams from the direct flame and high thermal cycling. That’s another of those built-in safety features.

One thing to note about the combustion tube is once it has reached 50 percent of its original thickness, the heater’s lifespan becomes very unpredictable and the tube’s strength and ability to contain the primary flame degrades rapidly.

Lastly, a full operational check in accordance with the aircraft AFM or POH should be completed.

While that pretty much takes care of preventative maintenance, Haskins shared two more insider’s tips on improving heater life.

“Pilots should also cool the heater down prior to landing,” he says. “Turn the unit off when you enter the pattern. This minimizes thermal stress on the heater and will help keep the overheat switch from tripping due to residual heat.”

And, while it may seem unusual, Haskins also suggests turning the heater on during the summer months. “This will ensure fresh fuel is running through the heater system and minimize the chance of clogged lines or residual moisture freezing in there when winter comes,” he says.

The heat is off …

OK, so let’s say the long trusted heater has gone cold as ice. Well, the first step is to troubleshoot the entire system. But where do you start? When it comes to troubleshooting tips, you can check out HET’s website at: http://www.hartzellenginetech.com/aircraft-parts/faq-service-questions.html#cabinheater-troubleshooting. You’ll find lots of helpful information.

New cabin heater technology from Hartzell

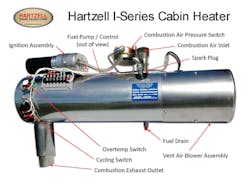

If all else fails, it’s time to repair or replace the unit. Replacing does offer the option of using a new-generation unit like the Hartzell I-Series unit.

If you have a Janitrol B-Series unit you can opt to have a heater shop like Haskins install Hartzell’s I-Series upgrade kit. The new combustion tube is a direct-replacement for the B-Series ceramic coated stainless tube, except the new I-Series the tube is now made of Inconel – the same material turbine (engine) blades are made from.

As an added benefit, upgrading a B-series Janitrol to HET’s I-Series is a way to eliminate the Airworthiness Directive (AD 2004-21-05) that pertains to that series of units. Hartzell’s new line of I-Series heaters is not affected by the AD. Owners can also exchange a B-Series heater assembly for a new or rebuilt I-Series through any HET distributor.

So what makes Inconel heaters so, well, hot?

The Inconel alloys are wrought nickel-iron-chromium-aluminum super alloys developed by Special Metals Corporation. Their unique formulation enables the Inconel materials to retain their mechanical properties in high temperature oxidizing environments like those found in turbine engine combustors, turbines and exhaust systems.

In the cabin heater, the Inconel performs better and is much less susceptible to heat erosion (that typically leads to burn-through) than the prior-generation method of applying a ceramic coating to the stainless steel. In addition, because Inconel requires no additional surface treatments, you eliminate any application inconsistencies that could impact longevity.

Of course, if you think that just because an aircraft’s cabin heater is not covered by any current ADs, the system is in the clear – think again.

“Some of the heaters in the older Barons are real problems,” Haskins says. “The old D83A28 units for sure. There is no AD on that heater and they will stay out in the field until someone finally does perform a pressure check and I can tell you they’ll fail nearly every time.”

“But the mechanic will say it was still working fine,” Haskins says. “They (pilots) may get a funny smell … but it still works.” Haskins stressed that situations like this are exactly why pilot/owners need to take a proactive role in making sure their combustion heater is in good working order.

Tim Gauntt is Director, Product Support, Hartzell Engine Technologies. For more information about the new I-Series cabin heaters contact your local Hartzell distributor, heater shop or visit: www.hartzellenginetech.com.

About the Author

Tim Gauntt

Tim Gauntt is Director, Product Support, Hartzell Engine Technologies. For more information call (334) 386-5400 or visit http://hartzell.aero/contact.