PFAS-Contaminated Drinking Water: A Growing Concern for Airports

The Environmental Working Group (EWG) estimates that as many as 200 million Americans may be drinking PFAS-contaminated water. And according to Northeastern University’s Social Science Environmental Health Research Institute, aviation facilities, including commercial airports, are listed as probable sources for PFAS contaminants found in dozens of public water systems across the country. Widespread PFAS testing and public acknowledgment of the results are in the early stages. These findings likely represent only a small fraction of PFAS-affected systems that will ultimately be attributed to aviation facilities.

Private drinking water wells near airports are also increasingly found to be contaminated with PFAS as more test results are reported. Recent private well PFAS contamination cases near commercial airports in the U.S. have been reported from Massachusetts to Alaska. For example, in Ohio, one of only two public water supply wells in the state with PFAS concentrations above the EPA Health Advisory Limit is downstream of a commercial airport. Upon discovery, testing of nearby private water followed and detected PFAS. This scenario can be expected to repeat in many communities over time.

After decades of aqueous film forming foam (AFFF) use either for training exercises or actual fire emergencies, some level of PFAS contamination can be reasonably assured at all aviation facilities. And in many cases, these "source areas" can continue to threaten downstream drinking water resources without a sound and effective treatment strategy.

Methods for Treating PFAS in Groundwater

There are two general types of approaches currently employed to treat PFAS-contaminated groundwater: ex situ and in situ. Ex situ treatments mostly involve mechanical groundwater extraction and filtration using media such as granular activated carbon (GAC). These pump & treat (P&T) systems have been reliably used to prevent the migration of organic contaminant plumes in groundwater for decades. If properly constructed, a line of extraction wells can form an impassive flow boundary that PFAS or other contaminants cannot cross.

P&T systems must be maintained to ensure effective operation. Part of the maintenance required includes routine sampling of the treated water to demonstrate PFAS removal effectiveness and changing out of the spent carbon. With the pending hazardous substance designation, the spent carbon from these systems will need to be managed as hazardous waste, resulting in substantial cost increases to maintain these systems.

Currently, there are limited opportunities to dispose of PFAS waste as landfills are turning it away and the EPA is now scrutinizing the incineration of the material as commercial incinerators may be generating unwanted toxic by-products.

More recently, groundwater remediation scientists and engineers have adopted an in situ PFAS treatment method. This approach uses a colloidal form of activated carbon applied directly into the groundwater. The colloidal activated carbon (CAC) treatment works by intercepting contaminants that move naturally through established groundwater pathways. To accomplish this, CAC is injected along a line of delivery points (i.e. wells or boreholes) into the affected aquifer zone to form a permeable reactive barrier (PRB). As groundwater migrates across the PRB, PFAS sorbs onto the carbon, resulting in a clean water discharge from the barrier's downgradient edge. The treatment, therefore, eliminates risk by eradicating the potential exposure to these chemicals through drinking water ingestion.

Material scientists developed CAC to overcome the challenge of evenly dispersing a solid injected material (i.e. activated carbon) through aquifer soils. This required carbon particles to be ground to one to two microns, equivalent in size to a red blood cell and small enough to fit through soil pore throats. However, due to hydrostatic forces that result in particle agglomeration, merely shrinking their particle size will not allow carbon to pass through these openings readily. Overcoming the clumping tendency of particles required forming the carbon as a colloidal suspension, made possible through a proprietary, drinking-water safe, anti-clumping treatment that cloaks the particles' surface charge. The result is that as CAC is injected, it moves through the soil pores but also coats them with a thin carbon layer that encapsulates the individual soil grains, in effect “painting” them with activated carbon.

In Situ CAC Treatments for PFAS at Aviation Facilities – Current Status

In situ CAC treatments have been used for the treatment of organic groundwater contaminants since 2014. These treatments have been applied at numerous PFAS-contaminated groundwater sites, including three ongoing pilot tests at aviation facilities – a former Army airfield and two commercial airports.

Camp Grayling Army Airfield, Michigan – In 2016, PFAS was found commingled with a chlorinated solvent plume that was migrating towards the property boundary. In reviewing remedial options, the Michigan Department of Military and Veteran Affairs chose to conduct an in-situ CAC PRB pilot test to halt the PFAS plume. PFAS were reduced from more than 100 nanograms per liter or (ng/L or ppt) to below detection limits in the first sampling event, approximately one month after installing the CAC PRB. PFAS have remained non-detect in all four downgradient well-pairs after nearly two years of post-application monitoring completed thus far. Tetrachloroethene (PCE) was also reduced and maintained below detection limits by the treatment.

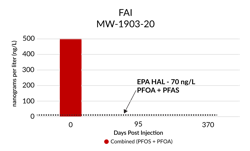

Fairbanks International Airport (FAI), Alaska - In late Oct. 2017, PFAS were discovered in the groundwater at the Aircraft Rescue and Firefighting (ARFF) training areas. PFOA and PFOS were detected above the EPA’s Health Advisory Level of 70 ng/L. An in situ CAC proof-of-concept pilot test application was completed in 2019 near MW-1903. The treatment has maintained PFOA and PFOS below detection levels from a starting concentration of 500 ng/L and reduced all PFAS by 97 percent (i.e., includes short-chain compounds) after approximately 1 year of monitoring completed.

A pilot test has also just commenced at Southampton International Airport in the United Kingdom with initial results pending in the coming months.

The longest running in situ CAC treatment for PFAS has maintained greater than 99.5 percent removal to detection levels for five years thus far. However, based on an independent, peer-reviewed model completed for the project, the treatment should remain effective for 50 years. This treatment was 17 times less expensive in a cost-comparison analysis than implementing an ex situ P&T approach, based on a very conservative CAC treatment longevity of 20 years.

In total, more than one hundred CAC treatments for PFAS projects are currently in the implementation or planning stages. All field installations applied thus far are meeting performance expectations. In a commitment to ensure the remedial approach meets objectives, performance warranties for CAC PRBs may be considered.

Ryan Moore, CHMM, is a REGENESIS PFAS program manager, focused on collaborating with environmental professionals and the industry to communicate effective, proven approaches to manage sites where PFAS contaminants exceed regulatory standards. Moore has managed the use of PlumeStop®, Colloidal Activated Carbon™, available exclusively through REGENESIS, to treat PFAS and other organic pollutants since its inception in 2014. Contact him at [email protected] or (219) 286-4838. Sammy Cummings, CM, development specialist, statewide aviation at the Alaska Department of Transportation & Public Facilities contributed to this article.

Mounting Public Concern over PFAS Leads to EPA Regulation

Public concern over PFAS has continued to increase with many PFAS-focused citizen action groups (CAGs) forming and collaborating. One of these collaborations, the National PFAS Contamination Coalition (NPCC), is an aggregate of more than 20 local PFAS CAGs across the U.S. Among their priorities outlined in a 22-point action plan, the NPCC is pushing Congress to create a one part per trillion (ppt) maximum contaminant level (MCL) for the entire PFAS chemical class.

Erin Brockovich has encouraged the CAG mobilization efforts, profiling PFAS at length and guiding her readers to organize and hold local water utilities accountable in her latest (2020) book, Superman's Not Coming: Our National Water Crisis and What We the People Can Do About It. A year prior, Robert Billot's best-selling book Exposure and the accompanying major motion picture, Dark Waters, were released to critical acclaim, detailing a personal account of his class action litigation against Dupont, who used the chemicals to produce Teflon®.

With a new Administration and growing Congressional support, these calls to action are now being received. On Jan. 29, 2021, the PFAS Task Force, a 132-member bipartisan Congressional delegation, submitted a letter to President Biden urging his administration to immediately act on the "growing PFAS pollution crisis." Included in their demands was to direct EPA to designate two types of PFAS, perfluorooctanesulfonic acid (PFOS) and perfluorooctanoic acid (PFOA), as "hazardous substances" under CERCLA, and clean up legacy PFAS pollution. On Feb. 22, the EPA moved a step closer toward satisfying these demands, making final determinations to regulate PFOS and PFOA. President Biden's pick to lead the EPA, Michael Regan, was confirmed in March 2021 and is anticipated to keep the pressure on the process to establish MCLs, having ordered one of the nation's first regulatory cleanups of PFAS as Secretary of the North Carolina Department of Environmental Quality (NCDEQ).

About the Author