Martha’s Vineyard Airport Selects CAC Approach in Pilot Study to Address PFAS

In 2018, Martha's Vineyard Airport (MVY) proactively conducted an environmental investigation, finding PFAS (per- and polyfluoroalkyl substances) in groundwater and worked with Tetra Tech, their environmental consultant, to determine the best and most sustainable approach to mitigate PFAS liability and risk.

Federally mandated fire safety testing and training exercises saturated the ground in the testing/training area with aqueous film-forming foams (AFFF), causing the 'Forever Chemicals' to leach into the underlying groundwater and form a PFAS contaminant plume. In response, MVY contracted Tetra Tech to develop a solution for treating the groundwater, with the treatment goal to stop PFAS contaminant migration away from the site.

Treating PFAS In-Place with CAC is Most Viable, Cost-Effective Solution

To date, remediating PFAS in groundwater involves either pumping the groundwater above the surface for treatment (i.e., pump & treat) or treating it in place (i.e., in situ) to remove the contaminants. After careful consideration, Tetra Tech recommended that treating the PFAS in place provided the most cost-effective, efficient, and sustainable option to meet MVY’s objectives.

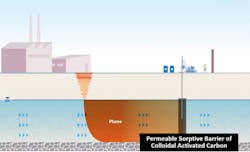

The in situ treatment approach employs a patented colloidal activated carbon (CAC) liquid amendment injected into the aquifer, which coats the aquifer matrix.[1] Each pound of the deposited CAC material contains 100 acres of surface area, creating an expansive, belowground pollutant filter that removes PFAS and other residual fuel contaminants used in the fire drills.

The CAC material is applied to the contaminated groundwater through injection boreholes placed in a line to intercept groundwater flow. This permeable sorptive barrier permits water to flow through it while capturing the contaminants onto the carbon (Figure 1).

CAC is a naturally-powered remedy that filters PFAS out of the groundwater belowground. Since no pollutants are brought to the surface, the process avoids generating costly PFAS waste streams. In contrast, pump & treat would create tons of spent filtration materials, requiring shipping hazardous wastes off the island for future disposal.

With no pumping required, the in situ approach also avoids long-term power consumption, greenhouse gas emissions, and operation & maintenance costs, all factoring into the remedy selection at MVY.

“One of the reasons we selected PlumeStop (CAC) was because it didn't have that ongoing operation & maintenance cost. And the fact that we don't have a disposal cost associated with it is certainly an advantage,” said Ron Myrick, Vice President, Tetra Tech

CAC Pilot Test Plan and Approval by Massachusetts Regulators

A CAC barrier was designed with a goal to prevent further PFAS plume movement away from the AFFF testing/training area for 15 years after a single application. To test the efficacy of this approach, a field pilot test was proposed downgradient of the AFFF source area (Figure 2). The pilot test plan was submitted to and subsequently approved by the Massachusetts Department of Environmental Protection (MassDEP).

Before installation of the CAC barrier, a flux measuring device was placed into a monitoring well (FluxTracerTM - patent pending) to measure and delineate the contaminant flux into the barrier. The information was used to refine the design according to the barrier’s longevity goal. While confirming the contaminant flux, this analysis determined that PFAS was moving through a more discrete zone than previously estimated. This more precise understanding of the contaminant flux achieved a more accurate barrier design and placement.

Field Pilot Test Application

In early December 2022, REGENESIS Remediation Services began installing the CAC barrier and completed it over five days, meeting the proposed timeline and safely navigating the project through the cold and inclement weather. The CAC was applied through temporary injection points advanced to the target treatment zone with a hydraulic percussion drilling rig (Figure 3).

A controlled injection rate was maintained during the application to direct accurate CAC placement, later verified by soil and groundwater samples documenting CAC's distribution throughout the target treatment zone.

CAC Barrier Rapidly Eliminates PFAS

The first performance monitoring sampling event was conducted 103 days post-injection, with samples collected from wells located on the hydraulically upgradient and downgradient sides of the barrier. The early pilot test results show the CAC barrier fully eliminating the six PFAS compounds regulated by the MassDEP (i.e., PFAS6) to non-detect levels (>99.8%) immediately downgradient (5’ DG Well). Additionally, PFAS6 concentrations have been reduced by 78% 25 feet downgradient of the barrier as the ‘clean’ water front propagates away from the barrier (Figure 4).

Colloidal Activated Carbon Offers a Long-Term Solution to Address PFAS Contamination at Airports

The CAC pilot test barrier at MVY exhibits typical early-phase results seen at other AFFF-impacted sites treated by CAC, including rapid PFAS elimination in the barrier/immediately downgradient and reduced PFAS concentrations further in the plume as the CAC-filtered groundwater continues to discharge out of the barrier. What is left to understand is how long this approach will continue to be effective.

CAC's viability as a long-term solution for PFAS contamination at airports was the recent subject of a research study titled Longevity of colloidal activated carbon for in situ PFAS remediation at AFFF-contaminated airport sites, authored by Dr. Grant Carey, an industry-leading groundwater modeling expert and President of Porewater Solutions. Based on the PFAS concentrations found at 96 AFFF-impacted sites, a performance review of 17 CAC field injections, and Carey's sampling and modeling analysis of AFFF-contaminated groundwater, the study suggests CAC treatments can eliminate PFAS exposure risks at airports for many decades following a single treatment. The CAC barrier at MVY is engineered for 15 years or longer of effective PFAS removal, consistent with the study's findings.

By eliminating mechanical infrastructure, decades of carbon emissions, and transporting hazardous PFAS waste materials off the island, the in situ CAC treatment approach has already proved beneficial for mitigating PFAS at MVY as pilot test monitoring continues.

Over 35 in situ CAC treatments for PFAS have been installed, including recent installations to treat AFFF releases at airports and airfields across the North America., Middle East and Europe. The inherently sustainable CAC technology replaces pump & treat approaches considered "expensive and ineffective for groundwater remediation" by the U.S. Government Accountability Office (GAO). Its implementation is poised to save billions of dollars in life-cycle costs and eliminate millions of tons of harmful greenhouse gas emissions globally at aviation facilities and other PFAS-impacted sites.

Maureen Dooley is the Vice President – Industrial Sector at REGENESIS.

CAC Permeable Sorptive Barrier Injection Details

· Contaminants of concern: PFAS

· Treatment Zone Geology: Coarse to fine sand, trace silt

· Barrier length: 60 linear feet

· Injection depth: 30 to 40 feet

· Injection layout: 24 points, 5-feet spacing, two staggered rows (Figure 2)

· CAC applied: 9,200 pounds/10,044 gallons

About the Author

Maureen Dooley

Vice President – Industrial Sector

Maureen Dooley is the Vice President – Industrial Sector at REGENESIS.