(Cary, N.C. – Oct.12, 2016) – LORD Corporation – a leader in the management of vibration, noise and motion control – has announced the FAA Designated Engineering Representative (DER) approval for optional installation of the tail skid weight on the Bell 206.

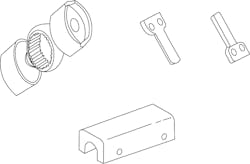

The tail skid weight, included in the LORD elastomer tail rotor trunnion bearing kit (P/N LB2-1010-20-1), is now an optional installation and only required as needed to assist in the dynamic balancing of the tail rotor hub assembly.

According to Rodolphe Leroy, Sales Marketing and Business Development Manager, LORD Corporation, this approval is significant since it is estimated that very few B206 require the tail skid weight for this STC. Operators will benefit from lower maintenance costs, extended life and reduced vibration without affecting cabin load or needing to drill into the tail skid. The STC ensures a dynamically balanced tail rotor hub assembly throughout the life of the LORD tail rotor trunnion kit.

The LORD tail rotor trunnion is specifically engineered for the Bell 206 to reduce maintenance time and keep aircraft in the air longer. Due to self-centering of the elastomeric bearing in the hub, installation is relatively quick and easy with no effect upon the static balancing procedures currently used. After the elastomeric tail rotor bearing has been installed in the tail rotor hub and blade assembly, installation on the aircraft remains the same. Dynamic balancing is accomplished with the same balancing equipment and procedures as currently used. The kit eliminates lubrication at 50 hours or after exposure to rain and snow, and eliminates grease from blades and blade feathering bearings – prolonging bearing life and improving aesthetics. Since the trunnion has been installed on hundreds of Bell 206 helicopters and has proven to deliver at least 2,500 hours between maintenance, operators are able to keep their aircraft flying an average of three times longer between tail rotor trunnion maintenance, therefore reducing costs. Further, reduced vibration levels alleviate pilot fatigue.

“LORD has decades of experience working with Bell on the 206 as well as other platforms, all with the joint goal of keeping pilots safe, while also minimizing unscheduled maintenance and costs,” said Leroy. “This option further solidifies our offering to provide the long-term flexibility for operators to maintain a proper dynamically balanced tail rotor hub assembly throughout the life of the aircraft.”

Operators that currently have the tail skid weight installed may choose to take no action if they are having no issues with dynamic tail rotor balancing. Operators can seek more technical information and/or installation instruction online.

For more information, contact LORD Corporation at +1 877 ASK LORD (275 5673).

About LORD Corporation

LORD Corporation is a diversified technology and manufacturing company developing highly reliable adhesives, coatings, motion management devices, and sensing technologies that significantly reduce risk and improve product performance. For more than 90 years, LORD has worked in collaboration with our customers to provide innovative oil and gas, aerospace, defense, automotive and industrial solutions. With world headquarters in Cary, N.C., LORD has approximately 3,100 employees in 26 countries and operates 19 manufacturing facilities and 10 R&D centers worldwide. LORD actively promotes STEM education and many other community engagement initiatives. For more information, visit http://www.lord.com.