Total Technical Care provider Magnetic MRO (www.magneticmro.com) based in Tallinn, Estonia launches High Pressure Compressor (HPC) Blades Boroblend Repair Service for CFM56-3, -5A,-5B and -7B Engines.

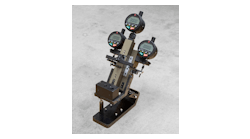

With the addition of HPC Blend Repair Capability, Magnetic MRO will be able to assist in AOG situations caused by FOD and be a very cost-effective solution for aircraft owners and airlines. The aforementioned service is performed on-wing and does not require engine removal or disassembly - access to the damaged blade is gained via regular borescope inspection ports.

On-site High Pressure Blade Blend repair advantages:

- speeds up engine serviceability

- shortens ground time – aircraft can be restored during the overnight stop

- cuts down engine operation costs dramatically UER (un-scheduled engine removal) can be avoided

- helps to create a prevention scheme by stopping crack propagation

On-Wing Support Engineers are available to perform the repair at customer’s location or home base on very short notice. „Magnetic MRO is constantly working on capability expansion along with expertise growth to offer customers a wider scope of Engine maintenance solutions“, says Ramil Sharov, Engine Line Maintenance Manager at Magnetic MRO.

About Magnetic MRO

Magnetic MRO (www.magneticmro.com) is an EASA certified Total Technical Care Organization headquartered in Tallinn. We have more than 15 years of MRO experience along with 16,600 square meters of hangars today. Our company is specialized in a wide range of services including management to line and base maintenance, engineering and consultation services.