EVENDALE, OH – October 31, 2013 – GE Aviation, in collaboration with the University of Cincinnati Research Institute (UCRI), has created the GE Aviation Research Center at the company’s world headquarters in Evendale, Ohio.

The Research Center enables GE Aviation engineers and scientists to collaborate with UCRI faculty members and UC students on the Evendale campus to pursue innovations that have direct application on GE’s future aviation products.

The scope of this agreement marks a “first” in Ohio between a leading aerospace company and a leading university research institute.

“Our business is growing significantly and we have considerable new technologies that must be developed and industrialized,” said Gary Mercer, vice president of engineering at GE Aviation. “We want UC’s best minds to be a part of our journey as we influence the future course of aviation. It is also an important effort to further enhance Ohio’s aerospace capabilities.”

GE Aviation, the Research Center’s sponsor, is investing almost $100 million in capital improvements at the Evendale campus to facilitate research efforts defined by GE and UCRI. In addition, GE has committed $6 million over the next three years to fund the six UCRI researchers and 19 UC undergraduate and postgraduate students who will work at the Evendale campus.

UCRI has also committed $1 million in funding over the next three years to purchase equipment to support the technology projects. Also, GE will benefit from UCRI’s considerable research and development experience in aerospace engineering. GE and UC have collaborated on aerospace projects for many years, and hundreds of GE Aviation employees are UC graduates.

“UCRI supports the collaborative process between industry and the university,” said David Linger, president and CEO of UCRI. “We work closely with GE Aviation to understand its business needs and drive efficient solutions.”

In 2012, the University of Cincinnati received a $5 million “Ohio Third Frontier” grant from the state of Ohio that will be used by UCRI to purchase equipment for the joint GE/UCRI research activities.

The multiyear research projects defined by GE and UCRI for the Research Center are:

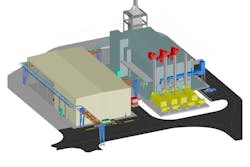

Advanced low-emission combustion. A building under construction at the east corner of the GE Evendale campus will house a new test cell for engine combustors. In the heart of a jet engine, the combustor is where compressed air and fuel are mixed and ignited to generate thrust. The test laboratory will evaluate the high compression rates demanded to achieve lower emissions in future engines such as the LEAP engine being developed by CFM International, a joint company of GE and Snecma (Safran Group) of France; and the GE9X. GE and UCRI will analyze new methods for burning fuel more efficiently and cleaner.

*Ceramic matrix composites (CMCs). GE has garnered worldwide attention as the first jet propulsion company to introduce components made of CMCs into the hot section of its future engines. The ultra-lightweight CMCs function in extremely high temperatures that enable lower fuel consumption and maintenance costs. GE and UCRI will test and evaluate these advanced materials properties in a realistic environment. CMC components will be introduced on the new LEAP engine, which enters service in 2016 on narrow-body aircraft; and on the GE9X engine, which enters service near the end of this decade on the new Boeing 777X.

*Aircraft Energy and Thermal Management. Airplanes are demanding more electricity. GE Aviation’s Power Distribution division in Dayton is responding to these requirements, and the Research Center in Evendale will study the thermal management challenges that these requirements create. GE and UCRI will link with GE’s Electrical Power Integrated Systems Research and Development Center (EPISCENTER) being constructed at the University of Dayton (UD). The EPISCENTER will team GE with UD researchers in the areas of computer modeling, simulation, and analysis of dynamic electric power systems and controls.

The GE Aviation Research Center further bolsters Ohio’s “I-75 Aerospace Corridor” with its world-class aerospace companies and universities spanning from the Greater Cincinnati area to the Dayton area, including GE, UC, UD, and Wright-Patterson Air Force Base. In addition, GE Aviation funds engine fan and materials research at Ohio State University.

GE Aviation has about 9,000 employees in southwestern Ohio, and supports several thousand more employees from area aerospace companies that do business with GE. GE envisions the Research Center as an important pipeline for attracting top engineering talent from UC to GE Aviation.

The Research Center is the latest in a series of significant steps taken by GE Aviation over the past six years to enhance Ohio’s aerospace presence. These actions include:

2007: GE Aviation’s engine test center at Peebles, Ohio undergoes $90 million expansion.

2007: GE Aviation acquires Smith Aerospace including two facilities in Dayton, Ohio.

2009: GE Aviation and the Ohio Dept. of Development partner to revitalize the Evendale plant. GE invests $100 million in Evendale complex over the next three years. As part of a 15-year Job Retention Tax Credit from the state of Ohio, GE Aviation commits to maintaining at least 5,000 area jobs for 18 years.

2013: The GE Aviation Research Center is established in Evendale.

2013: GE Aviation’s engine test center at Peebles undergoes a $70 million expansion.

Late 2013: GE Aviation opens the Electrical Power Integrated Systems R&D Center (EPISCENTER) at the University of Dayton campus in collaboration with the University of Dayton Research Institute.

2013-2015: During this three-year period, GE Aviation will have invested $300 million in its facilities in southwestern Ohio.

GE Aviation, an operating unit of GE (NYSE: GE), is a world-leading provider of jet, turboshaft, and turboprop engines, components and integrated systems for commercial, military, business and general aviation aircraft. GE Aviation has a global service network to support these offerings. For more information, visit us at www.ge.com/aviation. Learn more about GE Business & General Aviation at http://facebook.com/GEBGA. Follow GE Aviation on Twitter at http://twitter.com/GEAviation and YouTube at http://www.youtube.com/user/GEAviation.