UniWest Tie Bolt Inspection System Outperforms Other Testing Methods for Aircraft

(Pasco, WA) - Aircraft wheel tie bolts are extremely safety-critical, as they hold the two halves of the wheel together and must withstand the stress of landing. The landing of the aircraft, as well as the loosening and tightening of the bolts over time, can cause them to stretch and eventually crack. Broken bolts on the flight line often cause delays of departure. That is why airlines continually strive to employ the best available test methods to locate potential problems in the tie bolts.

Recently introduced, UniWest’s Tie Bolt Inspection System using eddy current testing (ECT) is now being used by major airlines as well as numerous aircraft wheel and brake shops that perform testing of aircraft landing gear.

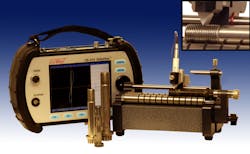

The Tie Bolt Inspection System—which includes UniWest’s US-454A eddy current instrument, the UniWest Tie Bolt Scanner (US-1779), and specialty probe US-1839—is used to perform eddy current inspection of the threaded area of the tie bolt and the underside of the bolt head.

Traditionally, both steel and inconel boltshave been inspected with magnetic particle or penetrant testing Non-Destructive Testing (NDT) methods. However, UniWest’s eddy current system was recently adopted by a major wheel and brake shop in place of three other inspection methods. Independent testing proved that UniWest’s Eddy Current Tie Bolt Inspection System could detect smaller flaws than other methods.

Eddy current testing of the threads using the US-1779 also proved more reliable than some Ultrasonic Testing (UT) methods because of bolt deformation. That is, since not all bolts are the same, this caused inaccurate or unreliable readings on certain bolt types.

UniWest’s US-1779 Tie Bolt Inspection System offers other advantages as well. The twin-roller flatbed allows quick inspection cycles for each bolt. The eddy current probe included in the system was designed to detect flaws in both steel and inconel bolts. No other probe is required. The robust probe tested more than 12,000 bolts during its field trials.

The system also features a go/no-go alarm set that is not dependent on the operator. The robust and highly sensitive UniWest eddy current probe also has been proven to detect smaller defects than the other methods of NDT for this application.

The US-1779 Tie Bolt System also takes up less space in wheel and brake shops than magnetic particle and penetrant testing systems, enabling the operator to perform the inspections in the production line, where it best fits for productivity. A modest 2-foot × 3-foot area with AC power is all that is needed. Productivity can be increased, smaller flaws can be detected more reliably, cost is lower, there are no chemicals to be disposed of, and bolts can be discarded during inspection instead of on the ramp while in service. Finally, since eddy current testing alone is required, training need only be done for one method of NDT.

“As of now, the Tie Bolt System is in demand in commercial and military aircraft industries, as well as wheel and brake shops,” noted Mark Gehlen, President of UniWest, “but this system certainly can be used for other applications requiring testing of bolt threads.”

To learn more, visit www.uniwest.com or call Bryan Leach at UniWest, 509-544-0720.

Founded in 1985, UniWest is a leader in applications engineering for nondestructive testing. The company designs, manufactures, and services a full line of dependable, robust eddy current and ultrasonic testing products custom-designed to fit each application. UniWest offers solutions to complex inspection problems for OEMs within the aerospace, power generation, automotive and other industries.