Study Confirms Double-Digit Savings From Rampmaster's Engine Management System

COATESVILLE, Pa., Jul 05, 2012 (BUSINESS WIRE) -- Rampmaster, the premier manufacturer of aircraft refuelers for the worldwide aviation market, has received the final testing report from West Virginia University's Center for Alternative Fuels, Engines and Emissions (CAFEE) confirming that an aircraft refueling vehicle outfitted with the company's patented Engine Management System (EMS) consumes up to 78 percent less diesel fuel while pumping its jet fuel -- a worldwide first in diesel fuel savings and greenhouse gas emissions. EMS is the first project released from Rampmaster's Center for Innovation, perfected over two years of R&D and field testing to provide refueling operators with ability to achieve unparalleled savings for every gallon of jet fuel delivered.

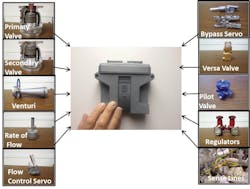

The technology was developed by Rampmaster's vice president of Engineering and Production, Owen Watkins, to combat the excessive inefficiencies of traditional pumping methods which run truck engines at a constant RPM during the fueling process. "No longer does a fuel truck have to waste engine fuel by moving fuel around in a bypass loop while the engine stays at a high RPM," explained Owen. "EMS allows the engine RPM to vary up and down depending on what the aircraft needs are."

After an extremely positive public unveiling of EMS at the NBAA 2011 show and Cygnus Aviation Expo 2012 both in Las Vegas, NV, West Virginia University's CAFEE, a non-profit research center renowned for its system of successfully measuring exhaust emissions of both conventional and alternative-fueled engines, was tasked with testing and confirming the fuel consumption and emissions savings yielded by Rampmaster's EMS innovation. In the 2nd quarter of 2012, CAFEE traveled on-site to evaluate fuel consumption rates and emissions from three aircraft refueling vehicles at varying refueling rates: a 2005 5,000 gallon competitor truck, a 2011 5,000 gallon Freightliner with a Rampmaster EMS, and a 2011 10,000 gallon Crane Carrier Company (CCC) vehicle, evaluated with and without the Rampmaster EMS. All tests were conducted to 40 CFR Part 1065 requirements. "When WVU delivered the final report, the results were even better than we anticipated," said Owen.

The Rampmaster EMS, when employed on the 2011 CCC chassis, resulted in significant reductions in fuel consumption -- from 45 percent up to 78 percent -- per 10,000 gallons delivered at all refueling rates. A comparison of fuel consumption rates between the competitor's truck and the 2011 Freightliner chassis equipped with the Rampmaster EMS also showed up to 43 percent reduction in fuel consumption per 10,000 gallons delivered at all refueling rates. In addition, according to the CAFEE report, "since carbon dioxide emissions are directly correlated to fuel consumption, any reduction in fuel consumption or increase in fuel economy will result in a corresponding decrease in greenhouse gas emissions."

"The savings in both diesel fuel and carbon emissions are unprecedented in the industry," said Owen, "and we're proud to be the company that is delivering this game-changing innovation to the market." Building upon the success of EMS, Rampmaster's Center for Innovation continues to develop leading-edge offerings for both the commercial and FBO aviation segments. Currently in development is a project that remotely monitors the fuel truck and actively alerts the operator of maintenance issues, so that forecasted and preventative maintenance can be automatically tracked. "Whether through EMS or our other innovative offerings, we're committed to furthering the refueling industry with top quality products that drive never-before-seen efficiencies," Owen added.

About Rampmaster

Rampmaster is the premier manufacturer of aircraft refueling solutions, known in both the commercial and general aviation markets for its technical innovation, quality production standards and superior customer service. Since its founding in 1968, Rampmaster has consistently delivered unprecedented product advancements that benefit customers' airport operations through longer refueler lifecycles, significant fuel and maintenance savings, lower EPA emissions and more.

Today, Rampmaster is global in scope, but remains an innovative and exceptional family-owned U.S. manufacturer, well known for re-investing capital to advance the refueling industry by way of thought leadership and quality craftsmanship.

About the West Virginia University Center for Alternative Fuels, Engines and Emissions (CAFEE)

A non-profit research center operating within academic surroundings, West Virginia University's Center for Alternative Fuels, Engines and Emissions (CAFEE) is an internationally recognized research program in the area of vehicles, engines, emissions and alternative fuels. CAFEE is a large research center involving over 50 faculty, staff, and graduate students, which have been conducting research specifically focused on fuels, engines and exhaust emissions since 1990.

Since its inception, the Center has conducted hundreds of research projects with total funding of over $80 million. The projects were or currently are sponsored by fuel suppliers (BP, ARCO, Chevron, Biodiesel Board and others), engine manufacturers (Cummins, Caterpillar, Detroit Diesel and others), vehicle manufacturers (Ford, GM and others), Federal Government Agencies (DOE, DOT, EPA, DARPA and others) and State Agencies (California ARB, Arizona DEQ, NY DEQ, TCEQ and others). These projects have addressed issues associated with the full spectrum of fuel, engine and vehicle performance. Emissions are measured in accordance with the Code of Federal Regulations (CFR 40) requirements for engine certification, which is used primarily for fuels testing, certification and verification procedures for the states of California and Texas.

SOURCE: Rampmaster