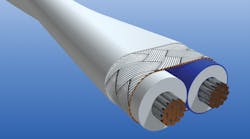

Gore focuses its efforts in four main areas: electronics, fabrics, industrial and medical products. The company’s electronic products division develops and manufactures high-performance copper and optical signal transmission products. Gore’s fabrics provide protection from the elements and enable wearers to remain comfortable across a broad range of activities and conditions. The products made by Gore’s industrial division meet diverse contamination control and processing challenges throughout industry. Implants from the medical division provide creative healing solutions to complex medical problems.

COMPANY OVERVIEW

COMPANY OVERVIEW

About W.L. Gore & Associates, Inc.

Contact

402 Vieve's Way

Elkton, MD 21921

United States

http://www.gore.com/electronicsElkton, MD 21921

United States

410-392-3700

800-445-4673

More Info on W.L. Gore & Associates, Inc.

More Info on W.L. Gore & Associates, Inc.

Products and Press Releases

Products and Press Releases

Request More Information

Request More Information

All content from W.L. Gore & Associates, Inc.

All content from W.L. Gore & Associates, Inc.