3D printing is a kind of a magic word in this moment in all development departments, all around the world, in all industry fields. 3D printing is promising things in aviation we could even not dream of just few years ago. We are definitively on the cusp of a new era in aviation and few new paradigm-shifting technologies are changing the world of aviation in a way not seen before. 3D printing and similar technologies seem to be to be an answer on many, even not yet made questions.

The innovative Additive Manufacturing (AM), also called 3D-printing technology is shaping the future of aircraft component manufacturing. Airbus is using AM and 3D-printing not only in prototyping, but also for parts manufacturing. AMT was able to visit the Airbus facility in Hamburg, Germany where AMT received an insight into 3D Printing and AM from Peter Sander, Airbus Emerging Technologies & Concepts, Germany.

First parts produced with 3D printing are beginning to appear on a range of the Airbus aircraft – from the next-generation A350 XWB to in-service jetliners, from the cornerstone A300/A310 Family to the Atlantic Bird 7 satellite, Atlante UAV, and THOR testbed. Thor is an acronym for 'Test of High-tech Objectives in Reality. (second image THOR first flight)

For the A350 XWB aircraft, Airbus already has produced a variety of brackets, made of plastic and metal, whose material and structural properties have been tested and validated, and are now incorporated, or will be on the company’s fleet of developmental aircraft.

3D-printing makes it simpler to produce very complex shapes: an electron or laser beam is used to model the desired material according to a computer-generated design. Therefore, parts designed for and manufactured by AM can have a natural and topologically optimized shape, which would be impossible to achieve from a solid block of material. AM parts are lighter, faster to produce and case by case ultimately much less expensive than conventional ones, because of unneeded tooling for example.

Advantages of 3D printed parts are many

Improved lead time (up to 75 percent), non-recurring cost savings through repeal of tooling (up to 90 percent), less energy use (up to 90 percent), weight reduction (up to 55 percent) and the reduced number of manufacturing process steps (now 50 percent compared to a milling process) are a few of the advantages. To this quantifiable savings there are many less quantifiable factors that are important like: Functional integration of features such as cooling channels, possibility to manufacture high-complex parts like hydraulic manifolds, considerable parts reduction (even up to 90 percent), and shortened R&D time. There is even the important possibility to manufacture highly customized products. (Images 5 and 6)

“We are on the cusp of a step-change in weight reduction and efficiency – producing aircraft parts which weigh 30 to 55 percent less, while reducing raw material used by 90 per cent,” says Peter Sander. “This game-changing technology also decreases total energy used in production by up to 90 percent compared to traditional methods.” In his words 3D printing is a real paradigm change as all involved in the production process have to learn that for the first time less use of material makes the part cheaper and more ecological. In the past, extreme lightweight construction meant huge development/manufacturing investment and the lightweight part was more expensive than a standard one, because the design and manufacturing was (and still is) more complex (more tools used, smaller radius machining, greater precision) thus more expensive.

According to Sander, despite several parts already being manufactured by use of AM and found their way in serial production, the industry is still exploring the technology limits and is learning what is doable. "Doable" doesn’t compulsory mean that the designers have yet completely understood why the printed parts have better properties; now a new design software is being developed on purpose for this new technology in a kind of a reverse engineering process. 3D-printed parts (most of them) are not yet price competitive with conventionally produced parts but this is an ongoing process and with higher number and better/faster machines the price break-even point will be reached soon. It's just a matter of time; but in the next two years this point is likely to be reached. The industry is right now investing billions in new production facilities that will be able to deliver bigger parts, and right now the parts dimensions are limited not by the technology but with the size of the machines.

How does the technology work?

AM, additive manufacturing, “grows” products in thin layers, from a very fine base material powder which is laser welded, instead of producing parts by means of mechanical removal of material. Base materials used in the AM process can be metals or plastics; the last one is used in a similar 3D printing process.

Both processes basically consist in adding thin layers of material in incremental stages from a (lowering) base to the top. 3D-printing allows producing very complex shapes, therefore, parts designed for and manufactured by AM can have a natural and topologically optimized shape. Data is delivered to the "printer" directly from computer-aided design (CAD) information.

The 3D-printing currently being used and developed by Airbus uses variations of two different building principles: Fused Deposition Modelling and Laser Beam Melting* (FDM LBM image)

FDM - Fused Deposition Modelling

FDM is used to manufacture plastic parts. 3D objects are built by printing fine layers of liquefied building material filament onto a building platform that fuse with the layer beneath. At the same time a support material is printed in order to allow printing of the building material further up the object of features that hang from the main structure. The build platform moves down incrementally to print the following layer. Once finished the printed support parts are removed.

LBM - Laser Beam (Powder Bed) Melting*

Airbus uses variations of powder bed melting for metallic materials such as titanium alloys.

3D objects are built by a fine layer of powdered building material leveled over the building platform, which is then exposed to a high powered laser (or electron) beam which welds (fuses) fine metallic powder particles together, joining them to the preceding layer to become the final "printed" 3D part. The welding occurs in small squares that don’t have to lay close to each other - usually are displaced all-over a welding -horizontal - layer to prevent creation of tension inside the built part. No melted powder remains in place and acts as a support for features further up the object that protrude from the main structure. The build platform moves down incrementally to ‘print’ the following layer. Once finished the remaining non-melted powder is removed and recycled.

*Laser Beam Melting (LBM) The industry standard term, chosen by the ASTM F42 standards committee, is laser sintering, although this is acknowledged as a misnomer because the process fully melts the metal into a solid homogeneous mass. The process is also sometimes referred to by the trade names DMLS or LaserCusing. A similar process is Electron Beam Melting (EBM), which as the name suggests, uses an electron beam as the energy source.

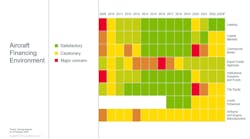

(Below 3 items in a Table/chart format)

3D-Printing Spares

Airbus is also working toward spare part solutions with 3D technology, which is ideal for on-demand production of cost-effective, out-of-production aircraft spare parts. February 2014, the first “printed” component – a small plastic crew seat panel – flew on an Airbus A310. (image 01).

The flight crew rest compartment bracket installed on A350 (image 02) is the example of a titanium, bionic AM component. Sander said to AMT that the lead time for such a part can be as little as one day, if the component is based on an existing design; redesigned parts can be produced in less than two weeks.

The ramp-up phase

3D-printing is being progressively integrated into new design and manufacturing in the supply chain, starting small but steadfast in the fields of prototyping, tooling, and on-demand production. Airbus has teamed up with major 3D-printing stakeholders to cover the process end-to-end, ensuring the production of certifiable structural components based on consistent tested material properties and meeting the requirements of a rigorous certification process.

AM in the line: print and go

Beyond its use to build parts that are already flying, Airbus Group is looking at using AM technology to avoid outstanding work during the manufacturing process. “Each time we have a missing part at assembly level it causes a significant disturbance and costs money for us to recover. AM can be used to manufacture missing and non-standard parts fast in low quantities,” says Airbus’ Bernard Duprieu. (His project team is developing a workshop capable of manufacturing customized parts in less than 24 hours.)

Final comment

The ultimate goal of AM is the reduction of cost and weight of aircraft parts, making aviation even more efficient, achieve set CO2 emission goals, and provide vital growth to the industry. AM/3D-printed parts provide significant advantages in terms of reduced weight, production lead time, and simultaneously reducing waste, energy consumption, and as a consequence the environmental impact.