Balancing the need for security screening against the fast and efficient handling of baggage is a constant challenge for airports of all sizes. The Transport Security Administration’s (TSA) introduction of pre-screening of passengers for expedited, standard or enhanced security processing will enable airports to take a more holistic view of the entire baggage handling process and to combine enhanced safety with an improved baggage handling efficiency and throughput.

Taking a holistic view helps unlock new efficiencies and cost-savings which may not be possible with segmented approaches which consider pre-security and post-security as two independent stages. An end-to-end review, however, requires that the airport, security services, ground handlers and baggage system integrators consider every aspect of how bags arrive at the right plane, at the right time.

The TSA’s three-tier approach to screening, combined with sorting technologies developed in the retail sector, could be the basis for a transformation in the way baggage is handled by airports throughout the United States.

In the United States, baggage screening is typically carried out in a number of separate screening locations throughout an airport. The reasons for this are understandable: most airports were built before the need for heightened security and so the screening process has been retro-fitted to the existing terminals and infrastructure. Often, the logical way to do this was to create three or four standalone security centers. This configuration minimizes the time that baggage has to spend on a conventional conveyor between the two main sections of the baggage handling process: from check-in to security screening and from screening to make-up.

Using multiple screening locations, however, means that each location needs sufficient screening capacity to cope with peaks in demand, and then additional screening machines to provide redundancy. In addition, the space allocated for these screening areas is real estate that airports cannot use for other purposes. The replacement of multiple screening areas with a centralized area, fed by a high-speed tote transport system, offers a number of advantages, including a reduction in the number of screening machines that are required to provide the same capacity and 100 percent traceability of all baggage.

FIFO

The conventional approach to baggage handling is essentially a First-In, First-Out (FIFO) process. As bags are checked in, they are screened and sorted to their proper destination.

This approach means that passengers have a fixed time-slot of about three hours before which they are not able to check in their luggage. During this time the loading gate for each individual flight has to be staffed by operators waiting for the next item of baggage to arrive on the departure carousel, together with bags for other flights, before loading the right bag onto the right ULD. Of course, some flexibility is provided by an "Early Baggage Store,“ which allows the baggage from the earliest passengers to be held pending loading onto the flight, but the process is essentially still one of pushing individual items of baggage through the system.

A comparison of the process used by the retail sector reveals the inherent inflexibility in the conventional baggage handling process.

The retail sector has developed processes to manage the high-speed, high-capacity sorting needed to provide next-day delivery of thousands of individual line items to thousands of customers around the world. A simple FIFO process would simply not provide the level of flexibility and speed that is essential in this highly competitive market. Instead, retailers use sophisticated warehousing technologies which can pick, sort, batch and dispatch individual items as they are pulled from storage by customer demand.

If this process is applied to baggage handling, the baggage is no longer "pushed" through the check-in, security and make-up process, but it is "pulled" by the ground handler for batch-loading onto the specific flight.

This new approach certainly requires a change in technology as well as philosophy, but the result is a baggage handling process which is faster, more secure and more flexible, both for the airport, the airlines and the passengers.

BAGGAGE WAREHOUSE

The inherent flaw in the conventional baggage handling process flow is that the ground handlers have virtually no control over the number of bags received at check-in, or the number of arrival and departure flights. The best that can be expected from this push-fed approach is that baggage flows smoothly through the system with as few delays or lost bags as possible.

The concept of the holistic baggage handling system, however, turns this around by creating a baggage warehouse as a buffer between the in-feed from check-in and the out-feed to the loading gate.

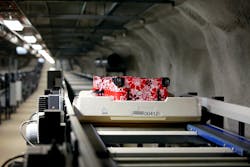

The process starts with automated bag-drops. These allow passengers to check-in their baggage at any time, rather than be restricted to a three-hour time-slot before the departure of their flight. At the self-check-in the passenger receives their boarding card and an IATA barcode tag to attach to their baggage before it is weighed and placed in an individual tote. The baggage tag is coupled to the embedded RF tag on the tote and the bag remains in the same tote through-out the complete check-in to security, and security to make-up process.

The holistic approach to baggage handling uses the concept of the Early Baggage Store and adds new capabilities to transform it into a baggage warehouse.

The bags which arrive from check-in are still in their assigned totes and they remain in-tote as they are held in this warehouse. As each flight approaches its scheduled loading time, the ground handling operator enters the number of the next departing flight and the control system identifies and retrieves the bags for that flight and transports them to the queuing lane for loading. Bags which have been checked-in closer to the flight departure can be flagged up as a priority to the centralized security section and called directly to the queuing lane as soon as they clear security. The ability to identify and prioritise bags which are required for imminent departures means that a higher percentage of bags will be successfully loaded onto the correct flight.

The function to call-up individual bags to create flight-specific batches of around 40 bags per batch means that the ULDs or carts for each flight can be speed-loaded, which has a significant impact on productivity. In the conventional system a member of the ground staff team would be in attendance at the gate throughout the three-hour loading period. With the flexibility provided by the baggage warehouse, the ground handler simply opens the position and speed-loads the batch of bags onto the ULD or cart before closing the position and moving onto another task.

The role that the baggage handling system integrator plays in coordinating efficiencies throughout this baggage handling value stream is crucial. Detailed analysis of every aspect of the entire, coordinated baggage handling process is the only way to ensure the most effective reductions in cost, improvements in handling efficiency, and the highest levels of safety in the working environment. The combination of a high-speed transport and sortation system, with a high-capacity baggage warehouse, solves the speed, tracking, storage and security challenges in one simple, end-to-end system.

About the author: Henrik Cort began working in the airport baggage handling industry in 1997 when he joined Crisplant, a member of the BEUMER Group. Since 2011, Cort has held the position of director of airport sales for BEUMER Corporation in North America, also part of BEUMER Group. The BEUMER Group designs, engineers, manufactures, installs and commissions security and sortation baggage handling systems.