The aerospace and aviation industry is a vast and diverse global industry serviced by an endless list of OEMs, MROs, specialty shops, and FBOs. If you are considering a career in aviation maintenance or changing jobs within the industry, there are two factors that you may want to consider. Do you want to work for a company that is operationally focused like an airline and OEM where change is usually brought about by alterations in route structure or the introduction of a new airplane or engine? Or, would you like to work for a company that is contract or project-focused and the work is usually very diverse and nonroutine. Many career coaches recommend that you follow your passion and do work that you like and that suits your personality. If you like variety, change, and interesting projects, I suggest you consider L-3 Communications.

L-3 is a huge Fortune 500 aviation company with diverse business divisions and service locations around the world. In 2009 it established the Platform Integration Division at the old James Connally Air Force Base in Waco, TX. The former base is now a modern industrial airpark operated by Texas State Technical College (TSTC). Platform Integration (PI) is a certified repair station and holds the FAA’s Organization Designation Authorization, the most current airworthiness certification authority.

Its MRO operations are supported by about 2,000 engineers; aircraft structure specialists, tool and die makers, systems mechanics, riggers, electricians, avionics technicians, cabinet makers, and interior craftsmen. If you like variety then L-3 PI is for you. The industry buzz is that L-3 PI Division is a good group to work for and has completed many interesting projects. I asked Lance Martin, L-3’s media contact, if he could give us a sampling of their projects. He said, “Some we can talk about in more detail than others” due to the sensitivity of the technologies or privacy guarantees to high profile customers.

SOFIA project

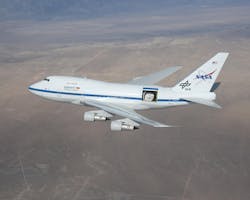

One of the high-tech projects was the Stratospheric Observatory for Infrared Astronomy or SOFIA project. This was about a 10-year project and one that took hundreds of engineers and maintenance staff to complete. According to NASA, SOFIA is “a world-class airborne observatory that will complement the Hubble, Spitzer, Herschel, and James Webb space telescopes and major Earth-based telescopes.”

The engine of the SOFIA observatory is a German-built 100-inch (2.5 meter) diameter far-infrared telescope weighing 20 tons that is mounted in the rear fuselage of a Boeing 747SP aircraft. PI had the responsibility for engineering, airframe modification, telescope mounting, and supporting systems installation and integration. It moved the pressure bulkhead forward, rerouted the flight control cables down the side of the fuselage, and fortified the airframe structure to accommodate the telescope compartment door that is about “16 feet wide and weighs about 3,500 pounds.”

It added new mechanical systems to operate the door, built a wind foil on the outside of the fuselage to spoil the air when the massive door was open, and installed a liquid nitrogen system so that the compartment and telescope could be cooled to match the outside air temperature when the door was opened. PI used a dismantled section from another 747SP as a full-size mock-up to ensure that concepts and dimensions were accurate before applying them on the actual aircraft.

U.S. Navy P-3 SMIP contract

Platform Integration also competes for modification and maintenance contracts that arise from the intelligence and defense sectors. Martin said that in June 2011, L-3 PI was awarded the contract “to perform aircraft sustainment for the U.S. Navy’s fleet of P-3, EP-3, and NP-3 aircraft. The sustainment, modification, and installation program (SMIP) provides for an intensive depot-level process for P-3 airframe and component inspection and deficiency identification. The program corrects deficiencies to ensure safe and reliable operation, as well as to enhance the aircraft service life.”

This is a long-term, heavy metal bill of work. The program goal is to keep the Navy fleet of 147 P-3s operational until they are replaced by the B737-800 P-8s. Senior structural specialist technician, Jason Brown, a 15-year PI veteran, spoke to the scope of work for the P-3 SMIP contract that includes: “accomplishing all required modifications, conducting phased inspections, repairing all found discrepancies, and refurbishing the outer wings.”

According to Brown, the P-3s are taken to the paint hanger and stripped. The wings are removed and fitted on special dollies, placed on freight liners, and trucked across Waco to the Wing Shop. Inspectors and the Nondestructive Team (NDT) have a look and document their findings. The structural work consists of repairing or replacing main wing surfaces, supporting stringers, brackets, and clips. While the wings are in the shop the NDT team conducts ultrasound inspections of the fuselage wing mounting structures, area skin, and the tail section. All systems modification and upgrades are accomplished during this visit. Depending on the findings, a P-3 can be in overhaul from nine to 18 months. After all the sustainment work has been completed, the refitted P-3 gets a new coat of primer and paint, and the Navy gets a serviceable aircraft ready for mission assignment.

Corporate culture

I commented to Lance that PI must have a work force with the skills necessary to fulfill the diverse contracts that come through the Waco Center. The SOFIA project and other surveillance and military projects would require electronics and avionics experience. The Navy’s P-3 SMIP project needs heavy structure specialists.

Martin asked Brown to weigh in on that discussion. He agreed that PI is a great place to work. “We are a big family with a lot of skills and experience. We really enjoy working on the variety of projects that come through PI. We all like the challenges of working on new and complicated projects. When we have a big problem, all the departments will pull together to solve it.” Asked if he had some tips for new AMTs or others looking to move to a division like PI, he said that “MRO operations are good places to work.

“Get your certificates, degrees, and work experience and be sure that you can work in confined spaces. You can come in through a program like the Texas State Technical College (TSTC) Aviation Career Education (ACE) program. I was hired through a predecessor to our ACE program many years ago.”

TSTC recruits qualified regional high school graduates into the ACE program where they complete the six-semester program and gain the necessary skills to become aircraft modification technicians. After demonstrating some success in the program, PI will pick up the student’s tuition and make them an intern. After students graduate and complete their internship, they must commit to two years of employment with PI.

I asked Martin about PI’s recruiting strategy. We recruit throughout the U.S. and collaborate with TSTC. “PI is like many similar companies. The work force is aging and we are seeing fewer candidates coming from the military and more coming directly from good technical and vocational schools.” He said that they “try to balance their work force with experienced staff and entry-level employees. Many of PI’s staff members have degrees and A&P certificates (not required but encouraged to get it).

Competitive strategies

In the aviation industry some companies do better than others during these periods of budget cuts and austerity programs. MROs and specialty shops can actually thrive because companies, including the military, will delay building or buying new aircraft or expanding their operations, so they keep operating their existing fleets. This usually means opportunities for major modifications, systems upgrades, or delayed maintenance.

PI is positioned to capture more projects and additional sustainment work. Martin said that the company is working smarter and harder to make sure that it fulfills the U.S. Navy’s P-3 SMIP contract on time and within budget. It is also making capital and process improvements at the Waco facility in order to be more efficient and competitive. It air-conditioned its hangars and moved parts and hardware plane-side. These changes created a more comfortable working environment and eliminated the queues at the tool cribs and parts department.

Coming attractions

I asked Martin what other interesting projects were in PI’s pipeline. The VIP Interiors and Head of State Completion Center staff in Waco is excited about an upcoming B747-8 project. “The new B747-8 is the largest B747 version, the largest commercial aircraft built in the United States, the longest passenger aircraft in the world.” The innovative interior and exterior enhancements to this airplane are going to be a “mind-boggling project.” Some MROs have all the fun!

Charles Chandler began his aviation career as a junior mechanic for American Airlines and retired after 27 years of service. After leaving American he held both line and staff positions in six other major companies. His positions with those companies included curriculum development specialist, manager and director for organizational development, management and leadership development, and maintenance training operations departments. Field Editor Charles Chandler has a Master’s of Science Degree in Adult and Occupational Education with a major in Human Resources Development.

About the Author

Charles Chandler

Field Editor

Field Editor Charles Chandler has a Masters of Science Degree in Adult and Occupational Education with a major in Human Resources Development. He began his aviation career as a junior mechanic for American Airlines and retired after 27 years of service. After leaving American he held both line and staff positions in six other major companies. His positions with those companies included curriculum development specialist, manager and director for organizational development, management and leadership development, and maintenance training operations departments.