Maintenance Welding: Selecting the Right Accessories to Get the Job Done

Welding in aircraft maintenance applications is rarely easy. In addition to joint complexity, there is also the matter of the specialized metal alloys that are used. Materials like stainless steel, nickel alloys, and titanium offer excellent corrosion resistance and extended service life; however, their highly reactive nature makes completing high quality welds challenging. Typically, welding procedures specify the GTAW (gas tungsten arc welding) process for the job, as it minimizes heat input to help protect against distortion or burn-through, and also offers precise control over the welding arc.

To achieve the benefits offered by these materials and to ensure the best weld quality, it is critical to have the right GTAW accessories. From the torch and tungsten to the proper personal protective equipment, the proper tools improve the success of the application, as well as the welding operator’s comfort and safety.

GTAW torches

The GTAW torch carries the welding current and directs shielding gas to the weld. On complex joint configurations with varying angles that are commonly found in aircraft assemblies, a torch with a modular design is an excellent choice. These torches allow for customization of a single torch body into multiple configurations by adding a flexible neck and/or different head designs. Modular torch designs also help minimize downtime for torch changeover and lower costs for purchasing multiple GTAW torches for each weld station.

A water-cooled torch design is preferred for higher amperage applications or those that require welding for long periods of time – they stay cooler than air-cooled models, making them more comfortable for the welding operator. These torches are also small, light, and easier to maneuver, which is advantageous when welding small components, thin sections, or in difficult-to-reach locations. Water-cooled designs require a separate cooling system, so their use is generally limited to shop applications. When portability is a factor, welding operators can instead rely on an air-cooled torch.

Both air- and water-cooled torches are typically available with flexible necks to ease joint access and positioning.

Cables, hoses, and leads

Welding operators can choose between vinyl or rubber compound hoses and cables. Vinyl cables and hoses are less expensive and are practical for light-duty GTA welding repairs; however, they are less flexible, making it difficult to maneuver the torch when out-of-position. Braided rubber compound hoses and cables provide better heat resistance and resist kinking, which prevents shielding gas disruptions and makes them more flexible and comfortable to use. The braiding adds to the durability of torch hoses and when color-coded, helps simplify connections and changeover.

Welding operators should use the shortest cable possible to help prevent voltage drop in the welding circuit and maintain the most consistent weld parameters. A 12 1/2-foot torch package is good for welding within a weld cell, provides more consistent arc starting, and keeps excess cables from cluttering the weld area. A 25-foot torch package is good for longer welds or for applications requiring greater movement; these cables are not ideal in a weld cell, since they may coil, kink, or cause a tripping hazard.

Having a good work lead and work clamp is also important. Welding operators should check regularly that the components are in good condition. Poor work connections disrupt the welding circuit, hinder arc starts, and create unwanted arc marking of the part that can lead to scrap or rework.

Front- and back-end torch consumables

Collets and collet bodies create the electrical connection between the torch and tungsten electrode to generate the arc, and they also distribute shielding gas around the electrode to the work surface. Look for consumables that can withstand the heat of the application without failing prematurely or creating an unstable arc. Avoid lower quality consumables – they may be less expensive, but they are often less heat resistant and their shielding gas ports may not hold the tolerances necessary for good gas coverage, leading to weld defects like porosity or atmospheric contamination (oxidation).

For best results, use a gas lens in place of a standard collet body. Gas lenses minimize shielding gas turbulence and increase shielding gas coverage. They also allow the welding operator to extend the tungsten electrode further out to gain greater access to complex weld joints and improve weld puddle visibility without sacrificing weld quality.

Another important component is the shielding gas nozzle. Nozzles direct the shielding gas to the weld puddle and protect it from contaminants. When access to the joint allows, select the largest nozzle possible for the application – the larger the nozzle, the better the shielding gas coverage. Choose high quality nozzles, too – ones with 95 percent alumina are ideal. Lower quality nozzles can have thinner or inconsistent wall thickness making them less durable and susceptible to cracking, especially at high temperatures.

Next, use the proper back cap – the component applies pressure to the collet in order to secure the tungsten electrode, and seals the back end of the torch to prevent shielding gas leaks and block outside air from entering. To improve joint access, consider using a short back cap or a medium one to access confined welds.

For optimum results on full-penetration welds or highly sensitive alloys, back purge – cover the backside of the weld with shielding gas to prevent contamination from under the joint. For longer welds, trailing shields (elongated components) keep shielding gas over the weld as the torch moves in the direction of travel, away from previously deposited metal, protecting it until it cools sufficiently below its oxidation temperature.

Tungsten electrodes and grinders

For the best results, use 2 percent ceriated and/or 2 percent lanthanated tungsten electrodes. Both offer excellent arc starting at low amperages and can be used in AC and DC applications to weld stainless steel, titanium and aluminum, among other materials. The 2 percent ceriated tungsten electrode can replace pure tungsten when AC welding on aluminum and also provides 30 to 40 percent more current carrying capacity. Both tungsten electrodes have a low rate of erosion and resist tip wear.

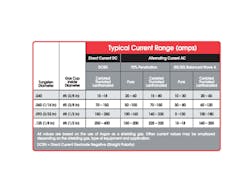

Tungsten diameter affects arc starts and arc width so select the smallest that can handle the welding amperage. Too small of a tungsten electrode won’t withstand heat from the arc, causing it to erode or even drop into the weld puddle, resulting in tungsten inclusions. See Figure 1 for recommendations.

Use the proper grinding accessories to prepare the tungsten electrodes. A fine grit-grinding wheel (Borazon or diamond) specially designated for the purpose works to prevent contamination. Using a specialized tungsten grinder, however, provides the best results, as it offers more precise grinding angles, especially if it has machined guides for given grind angles, and is usually capable of accommodating multiple tungsten electrode diameters. Some tungsten grinders offer cutting and facing features, and are available in portable designs.

Wireless remote foot controls

Cords, fixturing and tooling often restrict welding operators who weld in the aircraft maintenance industry. A wireless remote foot control allows for quick repositioning without untangling cords, saving time and reducing operator fatigue. It also eliminates expensive failures and downtime associated with damaged remote cords, and improves safety by reducing potential tripping hazards. Wireless models can typically operate up to 90 feet away from the power source. To simplify installation, some models allow the wireless receiver to plug directly into the same 14-pin connection as a standard corded remote. Advanced wireless technology also allows for uninterrupted communication and eliminates any chance for cross talk between remote controls, allowing them to be used in the same proximity.

Helmets, gloves, and more

Personal protective equipment (PPE) is essential and begins with the welding helmet. An auto-darkening helmet allows the operator to better position the torch for welding and eliminates the need to lift the hood to inspect the weld area. These helmets use an LCD that automatically darkens in the presence of the arc, which they detect through optical sensors. Welding helmets with an “X-Mode”, electromagnetically sense the arc and provide full protection when an arc is present, in the event the sensors are obscured. The “X-Mode” also eliminates interference from sunlight and out-of-position welding angles, such as those found in hidden-cavity welds. For GTA welding on small parts, welding helmets are also available with magnifiers to help improve visibility.

Select a lightweight helmet with a large enough window to allow for good weld visibility, and look for one that is adjustable and padded to improve comfort.

Look for GTAW gloves that fit snugly to provide the dexterity needed for intricate GTA welding applications and also offer heat protection, and for a lightweight welding jacket as added protection.

Welding operators should also wear safety glasses under their welding helmets as added protection when the helmet is up, or in case an object enters through the back of the helmet.

Final thoughts

It’s important to have the proper accessories for the job – especially for aircraft maintenance welding where the components aren’t always designed with weld joint access in mind. Choosing quality accessories helps to ensure accurate welding repairs for parts that must maintain their mechanical properties and corrosion resistance throughout their service life. Remember too, proper personal protective gear is essential to welding safety and careful selection will improve welder and operator comfort in the long run.

Brent Williams is technical contributor for Weldcraft and marketing manager, TIG solutions for Miller Electric Mfg. Co. For more information email [email protected] or call (800) 752-7620 or (920) 882-6800.