Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding is used in many aircraft applications. GTAW provides a clean, strong weld joint that makes it ideal for assembling and repairing various aircraft components. In this article, we will discuss the basic theory of GTAW and cover some basic welding and setup tips.

Basic Theory

In gas tungsten arc welding, a non-consumable tungsten electrode is used to establish an arc on the base metal. The heat of the arc melts the base metal and produces a weld pool. In contrast to normal arc welding, in GTAW an inert gas shields the weld area in order to prevent air from contaminating the weld. This shielding gas prevents oxidation of the tungsten electrode, the molten weld puddle, and the heat-affected zone adjacent to the weld bead.

In a typical GTAW setup, an AC/DC welding machine is used with a flow of shielding gas. The shielding gas goes through a regulator and flow meter and on to the torch. The torch has a collet/collet body combination that holds the electrode. A heat-resistant cup or ceramic nozzle surrounds the electrode and controls the gas shield.

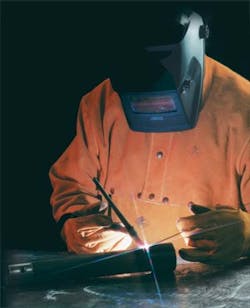

Personal Protective Equipment

Although GTAW does not produce the metal spatter that is common with arc or stick welding, it still generates intense heat and light. In fact, the clearer atmosphere around the GTAW arc can cause up to twice the amount of infrared and UV rays compared to normal arc welding. Any exposed skin will be damaged similar to an extreme sunburn. Welders must wear a welding helmet. Welder’s protective gloves and clothing should also be used. Fire-resistant cloth and leather clothing and accessories are recommended. Cotton should not be used as it doesn’t provide sufficient protection and it deteriorates quickly under the infrared and UV rays produced by the welding process. In addition, dark clothing should be used to reduce reflection of light behind the helmet.

Other Safety Precautions

The following general precautions should be observed to protect you and co-workers from the hazards associated with GTAW:

Ensure electrical connection leads are in good condition and tight prior to use. They should be protected to prevent accidental damage from hangar traffic.

Make sure you have adequate ventilation. Since GTAW uses inert gases during the process, if it is used in an enclosed area it can displace breathing air and can be hazardous without proper ventilation. In addition, ozone is produced during the welding process. The amount of ozone produced varies with type of electrode used, amperage, and argon flow. In poorly ventilated areas, ozone levels can increase to harmful levels. Whenever possible, draw fumes and contaminated air away when welding.

Flammable materials should not be carried in clothing pockets.

Shielding curtains should be placed around all jobs so that workers in adjacent areas are not exposed to the welding arcs.

Shielding Gas

In GTAW, the gas used to shield the welding arc and hot metals is an inert gas. Inert gases are gases whose atomic structures do not allow them to react with metals or other gases. Argon, helium, or an argon-helium mixture is used as the inert gas in GTAW.

Argon is a relatively heavy gas. It has several benefits when used in GTAW. It requires a lower arc voltage than other shielding gases for a given arc length and current used (ideal for thin metal welding). It also provides easier arc starting. Its heavier weight as compared to helium provides for good shielding with lower flow rates.

In contrast to argon, helium is the lightest of the inert gases. Because of its light weight, about two to three times more helium is needed as compared to argon to shield the weld area. Despite this, helium has an advantage over argon in that it can be used with greater arc voltages. Because of this, helium is preferred when working with thick metal sections.

Another difference in the two gases is their cleaning ability. Both helium and argon allow for good cleaning action when using DC. However, when using AC, argon provides for better cleaning action. Argon also provides better arc stability than helium when using AC.

Proper Gas Selection

You want to make sure to use the right gas with GTAW. Usually, pure argon is used, although thicker welding may require an argon/helium or other specialty mix. If you use the wrong gas mixture, such as a 75 percent argon/25 percent CO2 that is common for GMAW, the tungsten electrode will quickly be consumed or deposited in the weld puddle.

Gas Flow Rate

Setting a proper gas flow rate is another important element to successful GTAW. Contrary to what may seem to be common sense, more isn’t better. If you are welding in a flat position, a flow rate of about 15 to 20 cubic feet per hour (CFH) is typically adequate. For overhead welding, you can start at about 20 CFH and increase the flow by small adjustments of about 5 CFH if necessary.

So why is too high a flow rate a bad thing? Well, if the gas flows out of the torch at too high a velocity, it ends up bouncing off the surface being welded and starts a swirling motion parallel to the torch cup called a venturi. This venturi effect will suck air into the gas flow, creating an impure weld atmosphere. This results in pinholes in the weld.

Accessories

The GTAW torch can either be air cooled or water cooled. If most of the welding you do is at 200 amps or less, an air-cooled torch is adequate. If welding above 200 amps, a water-cooled torch should be considered.

Controls are also offered in either foot pedal control or torch control. Foot pedal control tends to be more popular where work is done in an area that affords mobility. A fingertip control can be beneficial when working in an awkward position or where less mobility is available.

Electrodes

Many different electrode types are available including thoriated, lanthaniated, ceriated, and pure tungsten. When choosing an electrode, follow manufacturers’ recommendations and choose the one that is best for you. Some characteristics to consider in an electrode are good ignition and re-ignition properties, constant arc, long lifetime, and high current-loading capacity.

As a safety note, 2 percent (thoriated) tungsten contains thoria, a radioactive element. When grinding on these electrodes, it is advisable to use some sort of collection device in the form of a vacuum or a liquid bath so that the grinding dust does not become airborne.

Good Welding Practices

You want to get in as comfortable a position as possible. Brace your arm to allow for steady torch movement. Many GTAW welders hold the torch like a pencil to afford the best control.

You want to hold the torch at the proper angle. If the torch is perpendicular to the work piece, it will be difficult to view the welding process. The angle of the torch relative to perpendicular should be about 15 to 20 degrees. If this angle is exceeded too much, it can lead to less penetration, poor shielding gas coverage, and general arc instability.

In regards to travel direction, the torch should be pushed away from (ahead of) the weld puddle. This ensures proper gas coverage of the weld puddle and offers the welder a good view of the weld puddle.

Get comfortable with your welding equipment. Practice welding on scrap metal. This is a good way to become familiar with the welding equipment, allowing for more confidence when doing the actual welding.

This article touched on some basics associated with GTAW. For more information, or to inquire about training opportunities available, contact the equipment manufacturer.

Additional ReSources

Lincoln Electric

(216) 481-8100

www.lincolnelectric.com

Miller Welding

(920) 734-9821

www.millerwelds.com