Borescopes have become an essential tool to help us properly maintain aircraft. We use them for scheduled maintenance requirements as well as non-routine events to inspect for defects. As an example, this article will focus on some borescope inspection tips for the Rolls-Royce AE 3007 engine. You will see it takes a change in mind-set of the way borescope inspections are done for mechanics that have never worked on this class of modern engine.

No scheduled borescope inspections

One thing that is new for mechanics to get used to when they are first exposed to the AE 3007 engine is that there are no scheduled borescope inspections. The borescope inspection on the AE 3007 engine is on-condition. So mechanics are only going to borescope when they have an indication of an anomaly.

Determining borescope requirements

So, with no scheduled borescope inspection requirements, how does maintenance know when an inspection is needed? What are the indications that would alert them of the need for inspection? Well, that’s where engine performance trending comes into the process.

Engine performance trending for the AE 3007A Series of engines begins with Embraer’s ERJ 145 family of regional jets Central Maintenance Computer (CMC) located in the cockpit. This computer is part of the avionics suite that comes with the aircraft. It electronically records a host of airframe, environmental and engine data. Monitored engine parameters include N1, N2, fuel flow, EGT or ITT, oil pressure, oil temperature, and vibrations. Various exceedence parameters are also monitored. This information is routinely downloaded every seven days.

Several options are available once the data is downloaded. Some airlines choose to monitor the data themselves in order to detect any adverse trends in engine operation. However, most operators choose to subscribe to a monitoring service provided by Data Systems & Solutions (DS&S) and supported jointly by Rolls-Royce and DS&S.

Using the DS&S monitoring service, operators are alerted to shifts in engine trends. Rolls-Royce and DS&S monitor the information on behalf of the airline. Should an adverse trend be detected, they jointly alert the airline and make recommendations. Rick Pataky, director of On-Wing care for Rolls-Royce, explains. “For instance, if there is a shift in N2 data, we would jointly go to the airline, either through an e-mail or phone call depending on the level of alert, and say ‘We’ve noticed a shift in N2. We recommend that you go out and do this at this interval.’ So it could be ‘go out and borescope your engine within so many hours’ or if it’s a significant shift, we may suggest they inspect it immediately. It depends on the level of shift, or the level of the problem. And the recommendations are always in accordance with the maintenance manual. So the operator will receive a recommendation per a specific maintenance manual task.”

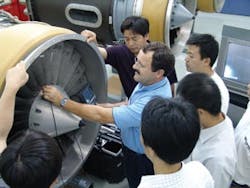

Borescope equipment

Once a borescope inspection is recommended, you need to be sure to use the proper equipment. Dale Hidy, an instructor at Rolls-Royce on AE 2100 and AE 3007 including borescope instruction, shares a tip on borescope diameter. “I would recommend an operator’s borescope equipment inventory includes a 3.9 mm borescope. Rolls-Royce says that you can use a 4 mm, and you can. However, what we have found is that if you use a 4 mm borescope extensively, the flexible jacket on the outside of the tip gets roughed up and worn. This ends up enlarging the effective diameter of the tip, and you can get it stuck in the engine pretty easily if you are looking in small areas.”

Borescope inspection

Once you have the proper borescope selected, there are a few inspection items on the borescope itself that you can do to help avoid big headaches down the road.

First of all, take a close look at the inspection tip. Hidy shares a few recommendations. “You need to ensure the tip is clean. One thing I point out to my students is when you go up through the gearbox, you are going past gears that have been slinging oil around, and it is easy to get some oil on the front of that borescope. This will give you a distorted view, and you aren’t going to have a true picture.” So you need to ensure the tip is clean before starting any inspection.

Walt Minnicks, another AE engine instructor at Rolls-Royce, further stresses the importance of borescope cleanliness. “You need to make sure that you’re making a decision based on good data. If there’s any doubt, you may want to take the borescope out and clean the tip again. Then go back in and try to get a repeated image. Most of the equipment we use today has digital photographic capability. And many of them also have measurement capability. If you’re going to make a decision, let’s say on whether or not to remove an engine, you want to make sure that your data is good and your view is not distorted by a dirty tip.”

In addition to cleanliness, you need to ensure that the inspection tip is secure before using the borescope. Always ensure that the tip is present when you remove the borescope from the engine.

When in doubt, call the experts

If you are not proficient in AE 3007 borescope inspection, you can rely on the team of experts at Rolls-Royce to help you out. Rolls-Royce has formed an On-Wing care group to help in just that situation. The technicians are on call 24/7 and will deploy to your facility when needed to perform just about any engine maintenance you need including borescope inspection. These technicians are familiar with the engine and can help get the aircraft back in the air quickly. In addition, they have direct access to support at Rolls-Royce - Indianapolis. Pataky explains. “If we see something in a borescope inspection that is marginal in terms of serviceability, we can go directly into our service engineering group and get technical variances and deem whether it’s serviceable or not. We can take video pictures or still pictures, e-mail them to our service engineering, and get quick disposition on the discrepancy.”

Training

When you are performing a borescope inspection, you always want to refer to the maintenance manual. Knowing how to identify defects and make airworthiness decisions based on that knowledge is essential. But knowledge of the proper use of the borescope itself is another critical factor for maintenance technicians. Whether through reading the operator’s manual or attending a formal class, be sure you are familiar with the borescope you are using in order to perform a proper inspection.

We have seen how the AE 3007 engine borescope inspections require a shift in mind-set from the traditional fixed-time inspection. We also have looked at some borescope inspection tips. With proper knowledge of the engine and borescope, we can help ensure these engines are properly maintained for a long and safe service life.