Performing major repairs and major alterations are the bread and butter of any general aviation (GA) maintenance business. Every year thousands of major repairs and major alterations are performed on older GA aircraft and this kind of re-mod work keeps a lot of GA repair shops solidly in the black. The downside of this arrangement is you must have FAA approved data to perform this kind of work and approved data is not something you can pull out of your back pocket when you need it.

Time-Consuming Process

So for major repairs and alterations you have to get a FAA field approval for the “acceptable” data you do have. But as every mechanic knows just getting an FAA field approval eats up a very large part of the mechanic’s and FSDO inspector’s time each year. How large? On the average, FAA FSDO nationwide, process between 22,000 and 25,000 field approvals a year. If you figure a very conservative total time of six man-hours for each field approval (industry and FAA) we are looking at a minimum of 132,000 man-hours a year you and I have to spend to get the job done.

The vast majority or about 65 percent of these field approvals are avionics upgrade installations. Despite the fact the FAA does not charge for the approval, and each FSDO office tries to keep the paper moving, I still get complaints from mechanics that say getting a field approval at the local FSDO is a lot like getting an elephant pregnant. It’s done at a high level, accompanied with much screaming and yelling, and it takes 19 months to get any results. Five or six years ago, I would reluctantly agree with them, but things are changing to speed up the field approval process.

What’s Been Done So Far

The first major change to the data approval process was the major revision to Advisory Circular, AC 43. 13-1B Acceptable Techniques and Practices, Aircraft Inspection and Repair in 1998. On the signature page of the AC there is a statement, signed by the Flight Standards Service Director, to allow the mechanics to make the determination if any one of the 56 “acceptable” repairs to non-pressurized areas he or she is going to perform is “appropriate,” “applicable,” and “not contrary to the aircraft’s manufacturer instructions” then that “acceptable” repair listed in the AC, is considered “approved.” This was a major step to reduce the overall number of field approvals for major repairs.

The second major change to the field approval process was the publishing of AC 43-210 on Feb. 17, 2004. This AC standardized procedures for requesting field approval data for major repairs and major alterations. This was the very first AC in 55 years that actually described what a field approval was, and how to request one from your local FSDO. Up until then, how to get a field approval was privileged insider information, and success or failure hinged on knowing who the “easy” inspector was in the FSDO.

New This Year

On July 28, of this year, something really big happened that affected field approvals for major repairs. On that date, the FAA published FAA Notice 8300.119. Now for the non-bureaucratic folks out there, a Notice is FAA headquarters instructions that are given to the field inspector about a change of policy or some other semi-interesting stuff. Since a Notice usually has a one-year time limit it does not have the job impact that an FAA Order does. So the Notice slipped under most FAA inspectors’ radar screens, including my own. When I finally read the Notice; it blew my socks off!

The Notice was a joint association between the Aircraft Maintenance Division, AFS-300 and the Aircraft Certification Division, AIR-100 and it allowed a mechanic for the first time in history to use the “acceptable” airplane manufacturer’s repair data in his maintenance manuals as “approved” data for major repairs on Block 8 of the Form 337. The mechanic still has to use the same decision tree process as in AC 43.13-1B to ensure the repair data is “appropriate,” “applicable,” and “not contrary to the manufacturer instructions” before approving the airplane manufacturer manual data for the repair.

Up until now the structural repair manual (usually Chapter 5) in the airplane maintenance manual had to be approved separately by the FAA. Now, that is not the case, because Notice 8300.119 changed all of that. The Notice will become part of FAA Order 8300.10 Airworthiness Inspector’s Handbook when the next change is issued around January 2006. You can read the Notice for yourself by pulling up the Regulatory and Guidance section at the FAA.GOV web site.

What About Alterations?

OK FAA, you did good with repairs but what about alterations? I am working on that. In June of 2004 I put in a notice of comment in the Federal Register and explained that I wanted industry comments on how to change AC 43.13-2A Alterations. I especially wanted comments on creating new policy to allow the “acceptable” alterations in the AC to be used as “approved data.” The comment period ran for one year.

A year is a very long time for the public to comment on proposed policy changes and I was asked over and over again “Why so long?” by my management and the folks in the Federal Register. I told them that I knew mechanics, and most are less than responsive to the Federal Register notices for comments unless money was involved. Plus, I argued, the longer time period allowed me to get the word out, both at the 40 IA seminars I conduct every year and write a heads up about the new policy in an article in this magazine. Despite a year to comment, and me running around the nation shooting my big mouth off, I got a total of 14 written comments and about 13 phone calls. Personal disappointment aside, I do want to thank those who did comment especially the JAARS organization in North Carolina for their support.

Committee to Help Write New AC

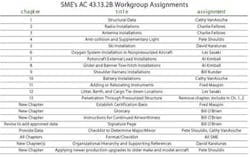

So with the low number of industry comments, is the project dead? No, it is alive and well due to the support of Dave Cann, AFS-300 division manager, I got the money to pull in eight FAA subject matter experts (SME) to help write the new AC. We met out by Dulles Airport on Sept. 13 and 14, 2005.

Prior to the meeting, I picked the best applicants for the SME positions from the individual responses to a FAA nationwide announcement. A total of eight SME were selected to form a committee to work on this project. I prefer using the term “committee” vs. the over-used word “team.” In the team concept everyone helps everyone else and the “team” is responsible for the final product. In my committee model, each individual committee member works solo, and is totally responsible for his or her work. One of the SME asked me what level of performance should the committee shoot for. I told him I am easily satisfied with excellence.

In the first hour of the SME meeting I explained that AC 43.13-2A was last revised in 1977 and was long overdue for change. Next, I defined the purpose of the project which is to set up procedures and delegate tasks in order to revise AC 43.13-2A Aircraft Alterations format to the latest GPO standard, create procedures in which the data in the revised AC can be used as approved data, and provide simple, noncomplex, generic alteration data for nonpressurized areas of general aviation aircraft of 12,500 pounds maximum gross weight or less.

I then explained the AC revision process is divided into four phases. Phase 1 was the public comment period and getting the old AC electronically scanned into Microsoft Word so the good stuff can be used if needed. I then added that Phase I was already accomplished.

Phase II is to rewrite the signature page to say the data within can be used as approved data. While this appears to be simple process, it takes a lot of coordination with Aircraft Certification and FAA General Council that must be done before this dream becomes reality. Since I was the resident bureaucrat, Phase II fell on my shoulders.

Phase III is the rewrite/overhaul of the current chapters of the AC and adding a couple new ones as necessary. Phase IV is making the AC bigger and better. This SME committee is assigned only to do the Phase III revision. Phase IV revision is for another time.

What follows is a list of the SME, and what they are working on, and their email address if you want to send them something worthwhile that would help them get the job done. However, please don’t bother them if you have nothing to contribute, or just want an ear for your pet peeve. I gave everyone a year to speak their mind and now these SME have been given an important job to do and a short timeline to do it in. Everyone will have a second chance to comment on SME’s work when I publish the draft AC in the Federal Register in August 2006.

Name, Location, Email Address

Catherine VanAssche, Long Beach, CA,

[email protected]

Charles Fellows, Washington, D.C.,

[email protected]

David Karalunas, Fairbanks, AK,

[email protected]

Albert Kimball, Orlando, FL, [email protected]

William C. Kunder, Reno, NV, [email protected]

Fred Maupin, Houston, TX, [email protected]

William O’Brien, Washington, D.C.,

william.o’[email protected]

Lester N Sasaki, Honolulu, HI, [email protected]

Charles Shouldis, Rapid City, SD,

[email protected]

AC 43.13-2b Revision Deadlines

Sept. 13, 2005

Begin project

Jan. 13, 2006

1st draft submission

April 13, 2006

2nd draft submission

June 13, 2006

Final draft submission

Aug. 13, 2006

FAA/Federal Register notice

Oct. 13, 2006

End of comment period

Jan. 13, 2007

Publish AC revision

In closing, if one of the SME happens to give you a call and asks for your help, I would be grateful if you give him or her a hand. These folks volunteered for this job and most assuredly, they will have to work on their own time to meet the established deadlines.

But their hard work will have a positive impact on industry and how the FAA will conduct business for a long time into the future. I conservatively estimate that having “approved” alterations data in the AC will alone reduce the number of field approvals by 28 percent or 36,960 man-hours the first year. It is reasonable to expect additional reductions in the neighborhood of 10 percent to 12 percent in the time spent on field approvals when more mechanics get used to the new AC policy. Once Phase IV is put in place a few years down the line, we should see an even greater reduction in the number of field approvals. The net result being all of these policy changes should keep you in bread and butter for a long time to come.