By now, most of us have had some exposure to the idea that hydrogen is the fuel of the future. From the President's State of the Union address, to numerous articles in technical and business journals, we are told that hydrogen-powered fuel cell vehicles may someday replace internal combustion engines that we have long relied upon to propel our personal cars, trucks and SUVs. The resulting, somewhat idealistic scenario is a transportation system based upon a pollution-free, renewable, abundant fuel that is not dependent upon politically unreliable foreign governments. While we continue to wait for that happy day to arrive; government, nonprofit organizations and commercial companies are searching for ways to turn the promise of hydrogen into a hydrogen reality. These efforts are leading to some unexpected conclusions regarding the first commercial applications for hydrogen technology that could very well include the GSE industry.

Most of the media attention on hydrogen has focused on passenger vehicle applications. Indeed, all of the major auto manufacturers have announced and/or demonstrated prototype fuel cell vehicles. Many of them have been featured on TV news shows and in national magazines. While passenger cars receive most of the attention from news sources, off-road vehicles such as industrial/warehouse trucks and ground service equipment vehicles are leading contenders for early fuel cell vehicle applications due to predictable duty cycles and favorable cost comparisons with battery-electric alternatives. Also, technical challenges with hydrogen storage and fueling infrastructure - huge issues for passenger vehicles - are more easily solved in a GSE application.

Hydrogen, the most common element in the universe, exists on earth only in combination with other elements, such as oxygen to form water or carbon to form hydrocarbons such as coal, oil and natural gas. To become a usable fuel, it must be separated from these other elements. By far, the most common method to obtain hydrogen today is via "steam reformation" whereby steam is combined with heat and natural gas to yield hydrogen. Hydrogen has the highest energy content per unit of weight of any fuel (making it a good choice for space missions.) However its energy density per unit of volume is very low - which means it must be compressed or liquefied when it is stored. As a fuel, hydrogen can be used in a fuel cell to generate electricity or it can be used in a conventional combustion engine. Either way, it is very clean, with almost no emissions.

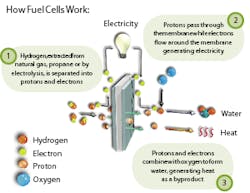

A fuel cell is an energy conversion device that combines hydrogen with oxygen from the air to yield heat, water and electricity. While there are different types of fuel cells, a Proton Exchange Membrane (PEM) fuel cell is the most promising for vehicles. The PEM fuel cell allows hydrogen to chemically combine with oxygen in the presence of a catalyst and generate electricity in the process (see figure 1.)

Fuel cells are approximately twice as efficient as internal combustion engines in providing usable energy to a vehicle. They have the added benefit of generating no emissions in the process. A 50-kilowatt fuel cell that would be about the size needed for a tow tractor is about as large as a two-drawer file cabinet - the type that fits under a desk.

Hydrogen Technologies are at a Transition Point

Hydrogen technologies are in the late development or early commercialization stage. For power generation, fuel cells are already being used for back-up and on-site electric generation. For vehicles however, there are still a few years to go. In fact, the US Dept. of Energy (DOE) has identified 2015 as its target year for the transportation industry to make commercialization decisions regarding mass deployment of fuel cell and hydrogen vehicles. What, then happens in the meantime?

The DOE views this interim time as a period in which to solve remaining technical challenges for hydrogen products. It has an ongoing $1.2 billion program to assist the development of hydrogen technologies through research, demonstration and validation projects. Other federal agencies along with state and local governments are also participating. Technical challenges that the DOE has identified include practical on-board storage options for hydrogen fuel, lowering the generation cost of hydrogen and finding economical ways to create a hydrogen distribution infrastructure. Consequently, the hydrogen industry is at an awkward crossroad. The basic technology has been proven to provide environmental benefits along with energy efficiency but hydrogen-fueled systems are still way too costly and inconvenient for most consumer applications. Deployment of hydrogen-fueled technologies depends, then, upon finding early applications for hydrogen where (1) the technology hurdles are not so significant, (2) the vehicle and fueling systems can be operated and monitored by trained technicians and (3) government participation is available either by operating or partially funding the technology deployment.

Hydrogen for Airport and GSE Applications

For these reasons and others, airports have emerged as excellent sites for demonstration projects that show hydrogen vehicles can be operated safely and reliably in commercial conditions. Airports, particularly in the largest urban centers, contain a variety of vehicle types and applications including fleets driven and maintained by trained operators. Since fueling occurs in central locations and the vehicles are operated in a planned duty cycle, range limitation and fueling infrastructure problems presented in other applications are diminished. Many promising airport sites are in emissions non-attainment areas where low or zero-emissions vehicles are encouraged or mandated by regulators.

In the US, there are already some hydrogen vehicle airport projects in various stages of development. The first operational airport hydrogen fueling station is at Los Angeles (LAX). Projects in development include fleets at Orlando, Dallas/Ft. Worth and Rockford (NW Chicagoland Regional Airport). Additionally, there are a number of military air bases that are considering hydrogen vehicle fleet projects. The vehicles that will be deployed at these and other airports include both off-road and on-road GSE.

Airport Vehicle Applications

Tow Tractors

Fuel cell tow tractors are being developed for both military and commercial use. A fuel cell powered tow tractor performs similarly to an electric vehicle, but is always "fully charged" without a performance drop-off at the end of a work shift. In many cases, hydrogen fuel could actually cost less than electricity for a battery-powered tractor. Fueling with hydrogen is much quicker than charging a battery and the tow tractor has the potential for doubling as an auxiliary power unit.

Hydrogen can also be used as a fuel for internal combustion engines (ICE). Ford Motor Company has developed a 4.6-liter V6 hydrogen-fueled engine that is being used by a major GSE manufacturer to develop tow tractors as well as other off-road vehicles. The hydrogen ICE has the benefit of providing near zero emissions, using a technology that does not require significant new training for an operating technician. Since ICE technology has a long track record, hydrogen ICE vehicles could quickly be inserted into a fleet as soon as a fuel source is established. While the hydrogen ICE is not as efficient as a fuel cell powered vehicle, the first generation of vehicles would almost certainly cost much less.

Buses

Diesel buses can produce emissions equivalent to 65 passenger vehicles. With such an impact on emissions and because they are operated in fleets, they are excellent candidates to demonstrate hydrogen-fueled systems. Consequently, several configurations of hydrogen-fueled buses have been developed by vehicle manufacturers.

Buses that use a compressed natural gas (CNG) blend with hydrogen, ICE hydrogen hybrids and fuel cell electric buses are under development and are being demonstrated around the globe. Any of these configurations could be used in shuttle applications at major airports.

Shuttle Vehicles

Vehicles for inter-terminal transportation, parking shuttles and rental car shuttles are another good application for hydrogen-fueled airport vehicles. Figure 3 shows a hydrogen fueled ICE airport shuttle vehicle.

By introducing these vehicles at airports - as well as for other fleet applications, a fueling infrastructure will begin to be established, making the eventual deployment of fuel cell vehicles much easier.

Establishing a Fuel Infrastructure

There are three basic alternatives for providing hydrogen fuel for an airport vehicle fleet: (1) hydrogen can be delivered from a remote source, either in liquid or gaseous form and stored on-site, (2) an electrolyzer can generate hydrogen on-site or (3) hydrogen can be generated on-site via natural gas reformation.

Hydrogen Delivery

Hydrogen can be delivered in one of two ways for on-site storage and dispensing. Gaseous hydrogen deliveries are suitable for a very small fleet (1 to 3 vehicles) or for backup to an on-site hydrogen generation system. A standard tube trailer at 2,400psig with 60,000 cubic feet of capacity contains hydrogen with about the same energy content as 140 gallons of gasoline. The hydrogen is compressed on-site in order to be dispensed into a typical vehicle tank that stores hydrogen at 5,000psi. A system such as this would be simple and uses existing, proven technology, however it yields hydrogen at a relatively high per unit cost.

Another way to deliver hydrogen is in liquid form. Some hydrogen fueling stations are using delivered liquid hydrogen. The California Fuel Cell Partnership station in Sacramento, and Shell's first hydrogen station in Washington, D.C. use liquid hydrogen provided by industrial gas companies. It is an existing, proven technology. However, up to 40 percent of the energy content of hydrogen is required to convert it from a gas to a liquid. Also, the transportation and storage of liquid hydrogen adds considerable cost and there is a continuous boil-off of liquid hydrogen, which must be vented into the air.

On-site Generation of Hydrogen: Electrolysis

An on-site electrolyzer can generate relatively small quantities of hydrogen required to fuel two or three cars. Theoretically, the electricity for these stations could be provided by renewable solar energy or wind power, but they are typically operated from electricity purchased from the utility power grid. While the electrolysis process is very clean, the original source of the electricity is almost certainly at least partially derived from coal or other hydrocarbon fuels. The current generation of electrolyzers require between 55--70kWh of electricity to produce one kilogram of hydrogen (approximately the same energy content as a gallon of gasoline). A PEM fuel cell will then convert the hydrogen back to electricity at about 60 percent efficiency. This is a very expensive way to generate hydrogen and, while possibly appropriate for small fuel cell demonstration projects, it has significant cost barriers.

On-site Generation of Hydrogen: Natural Gas Reforming

A promising alternative for generating hydrogen for airport fleet applications is to convert natural gas to hydrogen on-site. Most of the hydrogen currently produced in the world today is generated using a process called steam methane reforming. A steam methane reformer (SMR) can be scaled (most generate hydrogen in quantities up to several tons per day) down to a rate of 50--150 kilograms per day that is adequate for a small to medium sized fleet of hydrogen-fueled vehicles. On-site SMR's provide hydrogen that is lower in cost than either delivered hydrogen or hydrogen from electrolysis. Excess hydrogen generated by an on-site SMR can be used to generate electricity via a fuel cell for power generation. The biggest downside for this alternative is that SMR's are not widely available in this size range and are only just beginning to be deployed for fueling station applications.

A Hydrogen Fleet and Fueling Configuration for Airports

Airports are important early adopters for hydrogen technologies. In addition to environmental reasons such as emissions reduction for an airport ground support fleet, a hydrogen energy system, as depicted in Figure 7 can provide backup electricity for critical electronic systems in case of grid power failure. The system shown includes a basic hydrogen system which would provide "backup hydrogen" along with hydrogen generated from natural gas and dispensed to both on-road and off-road vehicles that are found at airports.

Long identified with emerging technologies, from the latest aircraft systems, security systems and even WIFI communications, airports are a good choice to deploy emerging technologies. Unique in their combination of quasi-government status, controlled access, high profile, multiple applications and availability of trained technicians, airports will be instrumental in proving the reliability and safety of hydrogen systems.

Clearly, embracing hydrogen has become a societal issue in which government has made the decision that economic, environmental and national security issues dictate the formation of a robust hydrogen industry. Airports and the GSE industry appear destined to play an important role in this process.