A 2002 FAA report titled General Aviation Maintenance-Related Accidents: A Review of Ten Years of NTSB Data notes that of the 1,474 NTSB maintenance-related GA accident reports analyzed, 295 (20.0 percent) cited installation as a primary cause or factor in the accident. The next three most frequently occurring maintenance activities included maintenance (217 or 14.7 percent), maintenance inspections (202 or 13.7 percent), and annual inspections (124 or 8.4 percent). Based on that information, installation and maintenance account for more than 34 percent of the accidents. In this article, we will go back to the basics to help prevent a maintenance-caused engine malfunction from occurring.

So why go back to basics? It boils down to a big problem in maintenance — complacency. Webster’s dictionary defines complacency as satisfaction accompanied by unawareness of actual dangers or deficiencies. In aviation, complacency can be catastrophic. Any of us is in danger of complacency, but especially those of us who have been working in the field for a while. So let’s step back and take a look at some of the basics we learned in A&P school to refresh our memory and help avoid complacency when working on turbine engines.

So what basic items should we focus on? Well, Pratt & Whitney Canada’s Customer Training Center has conducted informal surveys with its customers and also researched its engine reliability database and found that some of the top causes of maintenance errors are in the areas of incorrect torques, O-ring installations, and clamp installations. In the rush to get an aircraft out in a timely manner, it could be easy to overlook these items. So let’s look at these topics.

Torque

An old joke is that a while back, an aeronautical engineer caught his wife cheating with an aircraft mechanic. From that point on, engineers vowed to make mechanics’ lives as difficult as possible. We may be tempted to think that all the torque values we are expected to follow are a result of that vow. But following proper torquing procedures is critical to aircraft safety.

Many of us have fallen into the trap of using improper torquing techniques. Instead of going all the way to the tool room to check out that torque wrench, we just use our “elbow torque” to estimate how much torque we are applying. Don’t fall into this trap! Torques are specified for a reason, and not following proper techniques can be harmful.

When engineers design the aircraft, thorough analysis is done on the type of stresses that will affect each part. When the engineer designs a particular assembly, he takes into account all of these stresses that will be encountered as well as other factors like temperature changes, fatigue, and corrosion possibility. Fasteners are then chosen that will best fit the application and provide the necessary preload.

In order for a fastener to perform properly, it must be tightened accurately. Under-torqued hardware will result in inadequate preload. This can lead to unnecessary wear of nuts and bolts as well as the assemblies that they secure. Over-torqued hardware can exceed the design limitations of the structure or hardware and lead to a failure. Failure of the bolt or nut can result from overstressing in the threaded areas.

Applying Torque

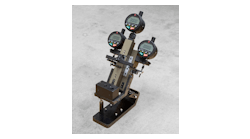

When choosing which torque wrench to use, try to select one that has the required torque in the second or third quarter of the wrench’s torque scale. The torque settings at the first and last quarter of a torque wrenches scale are not as accurate as those in the middle quarters.

Here are a few tips from AC43.13-1B to ensure that correct torque is being applied:

- Calibrate the torque wrench at least once a year, or immediately after it has been abused or dropped, to ensure continued accuracy.

- Be sure the bolt and nut threads are clean and dry, unless otherwise specified by the manufacturer.

- Run the nut down to near contact with the washer or bearing surface and check the friction drag torque required to turn the nut. Whenever possible, apply the torque to the nut and not the bolt. This will reduce rotation of the bolt in the hole and reduce wear.

- Add the friction drag torque to the desired torque. This is referred to as final torque, which should register on the indicator or setting for a snap-over type torque wrench.

- Apply a smooth even pull when applying torque pressure. If chattering or a jerking motion occurs during the final torque, back off the nut and re-torque. Note: many applications of bolts in aircraft/engines require stretch checks prior to reuse. This requirement is due primarily to bolt stretching caused by over-torquing.

- When installing a castle nut, start alignment with the cotter pin hole at the minimum recommended torque plus friction drag torque. Do not exceed the maximum torque plus the friction drag. If the hole and nut castellation do not align, change washer or nut and try again. Exceeding the maximum recommended torque is not recommended.

- When torque is applied to bolt heads or capscrews, apply the recommended torque plus friction drag torque.

- If special adapters are used which will change the effective length of the torque wrench, the final torque indication or wrench setting must be adjusted accordingly.

O-Rings

In the hustle and bustle of an aircraft maintenance environment, proper O-ring installation is another basic item that can easily be overlooked. Following good standard practices with O-rings can help reduce maintenance errors.

Inspect O-rings prior to installation. Look for manufacturing defects such as deformations, cuts, pitting, or cracks. Also check for extra material that may be left over from the manufacturing process.

Ensure the O-rings are lubricated according to the manufacturer’s maintenance manual. Using the wrong lubricant can damage the O-ring. Improper lubricant can also clog filters or fuel nozzles. Also inspect the O-ring seating area for nicks or corrosion that could cause a leak or damage the O-ring.

When installing the O-ring, install a protective sleeve over any threads it is sliding over whenever possible to help prevent damage to the O-ring. Try not to twist the O-ring during installation.

Clamps

Clamps play an important role in the engine area. With so many clamps to look at, it could be easy to become complacent when inspecting them. However, thorough inspection of clamps can help prevent a serious problem from developing down the road.

Inspect the clamps for proper cushioning. Worn clamps or clamps with out-of-position cushioning can cause chafing of the wires and tubing they were meant to protect.

Anytime clamps are replaced, check for damage to the tubing at the clamping location. Make sure the replacement clamp is the correct size. If it is too small, it can pinch and damage the wires or tubing. If it is too large, it will not hold the item securely as required.

Be careful when using solvents around clamps as an accidental spill on a rubber clamp can cause deterioration of the rubber and take away its protective properties.

Also check for proper clamp alignment. If a clamp is crooked, it can cause excessive stress to the wires or tubing.

Don’t fall into the trap of using tie wraps in place of clamps. Tie wraps are hard enough to cause serious damage to wiring, tubing, and engine frames. I have seen several cases of an engine frame trashed because a tie wrap was used and caused wear beyond limits on the frame.

In the end, it all comes down to safety. By going back to the basics and using proper techniques in torquing, O-ring installation, and clamping, we can reduce the chances of a maintenance-related accident occurring to an aircraft we worked on. Don’t let complacency cause a catastrophe in your shop!