Stormwater Management

Airport fueling facilities at mid-sized and large airports typically have secondary containment for above ground fuel tanks and truck loading/unloading racks. Many such airports do not have secondary containment for refueler staging areas or aircraft refueling areas. The use of high flow rate hydrocarbon absorbing filter media has wide application in passive stormwater pre-treatment systems and also in spill containment of water-borne fuel spills. This filter media is gaining acceptance in municipal, industrial, and aviation environments.

The primary function of secondary containment areas is to capture and contain fuel spilled during incidents, thereby preventing its release to the environment. Since these secondary containment areas are normally exposed to the elements, they also collect stormwater during storm events. This stormwater is potentially contaminated due to residual fuel in the containment areas, and therefore it must be processed on site prior to discharge.

Secondary containment is an environmental asset in terms of preventing infrequent fuel spills from reaching the environment, but an environmental liability in that it can generate contaminated stormwater, which causes disposal issues.

The sizing of storage tank containment areas is defined by the National Fire Prevention Association (NFPA) Standard 30 (Flammable and Combustible Liquids Code). The sizing of loading/unloading racks and refueler staging areas is addressed in 40 CFR 112, which covers the requirements for Spill Prevention, Control, and Countermeasure (SPCC) plans for facilities with more than 1,320 gallons of above ground oil storage, and the potential to discharge oil to the surface waters.

Once a site is under SPCC jurisdiction, the entire facility — including receipt of fuels, storage of fuels, transport within the facility, and dispensing within the facility — must be included. For an airport fuel facility, the fuel is within a regulated facility from the time it reaches the storage facility via pipeline receiving station or truck unloading rack until it is loaded into aircraft.

‘Sized’ containment

Refueling ramps are typically flat, impervious areas without secondary containment, except for that provided by undulations in the pavement and the inherent storage in the base of stormwater catch basins and piping between the fueling area and the point of stormwater discharge (if storm sewers exist).

Under 40 CFR 112, aircraft fueling is a regulated activity and “general” rather than “sized” secondary containment is allowed. This means that the SPCC plan certifier can determine the size of the most probable spill, rather than meet pre-determined worst case spill containment volumes stated within the code.

With regard to tanker truck unloading and aircraft refueler loading activities, 40 CFR 112 makes a distinction between “truck loading/unloading areas” and “truck loading/unloading racks”. The former is defined as an area where there are only unloading pumps and hoses associated with storage tanks; the latter is an area with a physical loading rack structure with loading or unloading arms and platforms to access the trucks. A truck loading/unloading area must meet the “general” secondary containment requirements, whereas a truck loading/unloading rack must meet “sized” secondary containment requirements. The sized secondary containment for loading racks requires that it be equal to largest compartment on any truck using the rack, plus an allowance for stormwater.

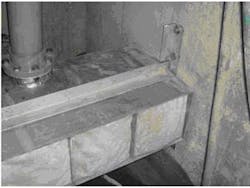

Under 40 CFR 122.26(b)(14), airports which have the potential to discharge contaminated stormwater to the surface waters of the U.S. are a stormwater regulated industry. Under this regulation the secondary containment area surfaces which contact fuel are considered to be “industrial surfaces” because of their frequent exposure to small amounts of fuel. The photo below indicates typical staining from minor jet fuel spills on a concrete truck transfer pad, which can lead to the discharge of contaminated stormwater.

Such fuel-stained surfaces have the potential to impact stormwater quality and when the stormwater discharges to a surface water body, a Storm Water Pollution Prevention Plan (SWPPP) must be prepared and implemented. The SWPPP defines a series of Best Management Practices (BMPs) that are used to minimize the discharge of contaminated stormwater and required annual inspections and/or testing.

If testing indicates that hydrocarbon-contaminated stormwater is being discharged, then the impacted stormwater must be pre-treated before discharge to ensure compliance with State Pollutant Discharge Elimination System (SPDES) requirements. Such discharges are illegal and when discovered by either the state environmental agency or Coast Guard, legal action will be instituted against the airport operator and/or fueling system operator.

The federal SPDES regulations govern only stormwater discharges from regulated industries to surface waters, and stormwater discharges to groundwater would appear to be unregulated. However, many state SPDES programs address discharges to groundwater where drinking water aquifers are potentially impacted, and federal programs related to re-injection wells may preclude the discharge of petroleum contaminated stormwater to groundwater.

Conventional Oil/Water Separators

Most bulk fuel facilities utilize buried API gravity type oil water separators to process stormwater captured by secondary containment areas.

Depending upon specific design factors, these are passive devices that cause small fuel droplets entrained in the stormwater flow to coalesce and float to the surface of the separator, where they are retained by a diversion baffle.

These devices typically reduce total petroleum hydrocarbon (TPH) levels in the effluent stream to between 10 and 20 parts per million (ppm), provided they are properly maintained and cleaned out on a regular basis to remove sludge and slime build-up. One disadvantage of such systems is that they do not remove dissolved or emulsified fuels, and therefore can result in a stormwater discharge exceeding the limits for dissolved or total hydrocarbon contaminants under a (SPDES) permit. This situation necessitates the installation of an active pre-treatment system downstream of the oil water separator. Such systems are expensive to install and operate.

Oil/water separators are typically sized either to handle specific flow rates or to contain a specified volume of scavenged fuel. Oil water separators are typically designed to store captured fuel up to 50 percent of the working capacity of the separator. The largest transportable oil water separator is 60,000 gallons, which has a fuel storage capacity of approximately 30,000 gallons and can handle a flow rate of 5,000 gallons per minute (11 cubic feet per second) which corresponds to a 24-inch diameter storm drain pipe. The purchase price of a 25,000 gallon oil water separator is approximately $125,000 and the installed cost can exceed $200,000 under high groundwater level conditions.

For larger stormwater flow rates corresponding to major aircraft refueling ramps, several of these large units must be installed to handle the peak flow rates.

Passive stormwater filtration systems

Filter media designed to absorb hydrocarbons from water have been used in the past for stormwater pretreatment (ie: activated charcoal or Imbiber Beads) but they were plagued with high cost and flow resistance which precluded their use in high-flow stormwater installations typical of airports.

Recent developments in polymers have led to low-cost, high-flow rate absorption filter media. These absorption filters can be used not just to polish the effluent from an oil water separator, but in cases where the influent is relatively clean, they can replace the oil water separator, thereby producing a superior effluent quality at a much lower capital cost.

Typically, tank dike stormwater is sufficiently clean to be processed by absorption filters without oil water separators, as is stormwater from aircraft refueling areas and refueler staging areas. Truck loading and unloading racks tend to have more contaminated stormwater runoff and are more likely candidates for oil water separators.

These passive stormwater absorption filtration systems are starting to find widespread application in municipal stormwater systems in California and New York. The filters are used at the source (catch basin inserts), mid-stream (in buried vault systems), and at end of pipe (at the point of discharge).

Absorption filter media is preferred over adsorption filter media because when the media is saturated, the fuel cannot be removed by squeezing and therefore they are suitable for landfilling or waste to energy incineration. This type of filter media typically removes more than 95 percent of the hydrocarbons in the inlet stream, whether free product, emulsified fuel, or dissolved fuel.

When the filter media becomes saturated, typically at 300 percent of the dry media weight at the time of installation, it must be replaced. In the past, the high cost and limited absorption capability of such filter media have relegated its use to final polishing of low volume streams where the hydrocarbon concentrations are very low.

One disadvantage of passive absorption systems is that they can be overpowered by a large spill of fuel — once they become saturated with absorbed fuel, additional fuel will pass directly through them. This can be prevented by the addition of an oil stop valve upstream of the absorption filter media.

Oil stop valves stop the flow of raw fuel by means of a ballasted float, which is designed to sink when submerged in fuel and float when submerged in water. They are relatively low cost and are available in sizes up to 12 inches in diameter with a rated flow of 1,400 gpm (3 cfs). An oil water separator consisting of a 12-inch oil stop valve followed by an absorption filter with a frontal area of 25 square feet (5x5 feet) would provide pre-treatment of 1,400 gpm of stormwater.

Pre-Treatment of Stormwater Discharges

Larger airports normally have stormwater systems which are very similar to municipal storm sewers. A series of concrete catch basins with high-strength metal grating are connected by concrete pipe and typically lead to a headwall where they discharge to surface waters or to excavated recharge basins for discharge to groundwater. Flow rates can be very high during major storm events, due to the large impervious watersheds that airport ramp fueling areas represent.

The first flush of stormwater from aircraft refueling areas can contain appreciable traces of fuel from accumulated minor drips or spills which cause stains on the fueling ramp. If a larger spill occurs during dry periods, it will normally be retained in the bottom of catch basins in the storm drain line and it will not reach the outfall.

However, in the event of a larger fuel spill on the refueling ramp during a storm event, the spilled fuel can be entrained in the stormwater flowing through the stormwater drainage system and reach the outfall, resulting in a reportable release to surface or groundwater.

Pre-treatment of such stormwater can take place in one of three locations;

- At the source (each catch basin in a fueling area);

- At or near the end of pipe (vault or filter box on outfall);

- Immediately beyond the end of pipe (containment boom on surface waters).

Pre-treatment at the source (catch basin) requires the insertion of a filter rack and filter media into each catch basin to process the stormwater as it enters the catch basin. For small airports with a limited number of catch basins in the fueling ramp, this approach may be the most cost-effective way to treat the first flush issue. However, filter maintenance can be problematic, as it has to be done at night between parked aircraft and parked ground support equipment in a high security area.

The photo below depicts a high-performance absorption filter catch basin insert in service at the bulk fuel facility at Newark Liberty International Airport, where Allied Aviation was proactive in meeting bulk fuel facility stormwater discharge requirements under NJDEP permit requirements. This filter strips hydrocarbons from stormwater in a curb inlet for stormwater, ensuring that the discharge is free of hydrocarbons.

The photograph below indicates absorption filters installed in an underground vault to treat stormwater flowing in a buried pipe prior to the point of discharge, in a residential storm sewer system in Babylon, NY.

The next photograph indicates absorption filters installed in an end of pipe discharge at Newark Liberty International Airport. The absorption filters are downstream of a conventional oil water separator and they are used as final treatment prior to discharge.

In situations where there is insufficient space to retrofit conventional oil water separators into existing stormwater drains at an aircraft refueling ramp, the use of permanent booms can be used to perform the function of removing sheen from stormwater and containing any fuel spills that migrate through the storm drain system to surface waters.

The associated photograph shows a conventional spill containment boom in place at an outfall from an aircraft refueling ramp at Newark Liberty International Airport. The purpose of this boom is to capture sheen and spills from the aircraft fueling ramp that travel down the storm sewer system. Most containment booms have been developed for emergency response use, which involves short-term deployment rather than long-term use.

At Newark Liberty International Airport, a study is underway to update the boom system and add absorption filter media behind the booms to prevent fuel passing under the booms due to current conditions or over the booms due to wind conditions. The photograph below indicates a newly developed permanent boom system being considered in the study.

Where the stormwater outfall discharges via a headwall into surface water body, the use of spill containment booms at the outfall can prevent the flow of spilled fuel from spreading on the surface water body.

Such booms typically can retain a layer of fuel up to four inches thick within the boomed area. By sizing the boomed area, adequate spill retention can be achieved for spills of a few hundred gallons. The disadvantage of booms is that they will start to leak fuel when the current reaches a velocity of approximately .85 mph. This is caused by the flow of water under the boom skirt entraining fuel drops and causing fuel to be carried past the boom.

Under high-wind conditions (above 15 mph) wave action can also cause fuel to be pushed over a normal boom.

Stormwater outfalls at large airports typically have very high flow rates during storm events. A four-foot diameter stormwater pipe (which is not large for airport stormwater systems) can convey up to 54,000 gpm (120 cfs) and the use of in-line adsorption media filters is not practicable at such high flow rates.

For such stormwater outfalls, it is normally more cost-effective to capture the fuel beyond the end of the outfall pipe by using a spill containment boom where conventional oil water separators cannot be installed. Such outfalls require approximately one linear foot of boom for every cubic foot per second of flow from the outfall. The upstream side of the boom must have absorbent filter booms installed to capture fuel and prevent boom leakage under high current or wind conditions. The presence of this absorbent boom ensures that hydrocarbons in the first flush of stormwater are removed cost effectively.

N.D. ‘Dennis’ Eryou, Ph.D., P.E. is an engineer in private practice with 25 years experience in aviation fueling systems and environmental issues. He can be reached at [email protected]