Making History

Q: How did you get involved in the industry?

A: I started with the company as a flight attendant and was injured on the job. During recovery, I was placed in the SEA GSE shop and learned the administration side of GSE. One of the managers I worked with was determined to make a technician out of me, so I spent time in the shop, even completing services on equipment. He used to say, “How can you order parts if you don’t know the application?” And he was right. I also had to transfer technician equipment work orders to excel spreadsheets and after years of reading daily work orders, I’ve gotten good at knowing what should be done, how long it should take and what parts are used and/or needed.

When the manager position opened up here in the shop, I approached our system manager, Brad Wegner, about putting in for the job. He didn’t think I was ready, but was very supportive and encouraging and laid out a plan to get me where I wanted to be. When the new manager, Bud Thompson was brought in, he too was wonderfully supportive and we spent the next year getting me ready. When Bud transferred to another department, the position opened again and this time I got it.

Q: What are some of the major trends you have seen developing over the past decade?

A: An increased emphasis on preventative maintenance. I know it sounds like a no-brainer, but there are substantial cost savings in having an aggressive maintenance program that not only prevents equipment failures, but anticipates the changing needs of our customers and begins preparing for those changes.

Preserving the environment is also a huge focus for us. Horizon has been recycling for the entire 18 years I’ve been with the company. Over the last few years, our focus has been replacing motorized equipment with electric and now about 48 percent of our fleet is electric with more on the way.

AIW workshops have been another focus for us. We’re taking a look at how we’re doing business and making it better, doing it better and keeping it better! In 2007, we held a workshop in our Seattle shop and the results were fabulous. We gained about 500 square feet of useable workspace. We have a dedicated workspace for each technician, a dedicated deicer work area and we also sorted and labeled all our parts. It was surprising how many parts we had on hand for equipment we no longer even own.

Q: What advice would you give to those new to the industry?

A: I would advise anyone new to the industry to get out and work side by side with those who actually use the equipment on a daily basis. Know your customers! Does the equipment work for them? Does it fit the application? And if not, you’ll know first hand what changes need to be made or the procedures that need to be revisited. Also, don’t hesitate to discuss equipment problems with your peers, more often than not, if you’re experiencing problems, they are too.

Q: What in the industry keeps you up at night?

A: Winter operations. During the winter months, we shift priorities to where our deicers are first on the list. It’s imperative that we keep them up and running for our customers. Like every piece of machinery, components fail and that weighs heavily on me. In some of our small cities our deicers are the only ones on the field, so we’ve got to be ready to respond 24/7.

Q: Is there one accomplishment that you are especially proud of?

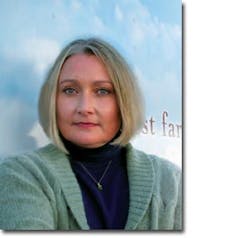

A: I am especially proud to be the first woman GSE manager in the history of Horizon Air, and to be working for a company that continually encourages its employees to step out of the box.

Q: Where do you see Horizon GSE in 5, 10 years?

A: We must continue to bring real value to Horizon Air in this time of rising costs. It’s imperative for any organization facing skyrocketing costs to look over the entire operation for savings. GSE has to find innovative ways to contain costs and increase productivity and demonstrate those savings to the company.

In some of our cities, we contract out our GSE repairs and while we value these relationships immensely, it’s still not the same as having a company technician arrive on the scene. Our contractors do a great job, but our folks are owners. When they arrive at a station, they’re not only going to make the repairs, they’re also going to check out all the equipment to see if anything else needs repair. While they’re at it, they’ll make note if a seat needs replacing, or an ala cart cover is showing wear and they’ll even help load a few bags before they leave.

For the full interview, visit www.groundsupportworldwide.com.