Aerospace Hose Assemblies

Aerospace hose manufacturers are frequently asked how long an aerospace hose assembly should last. There is no clear answer because any particlar hose design may serve many applications. Obviously, an engine application may cause heat-related damage; a hydraulic application may cause pressure related damage; or a hose installation that has a tight bend may suffer handling damage.

The only way to evaluate how long an aerospace hose assembly should last depends upon its configuration and application. The best means to evaluate the hose life is to collect life data by hose part number and its related application, and then use a statistical tool such as WEIBULL to characterize the applications related aerospace hose life.

How do our armed forces manage hose life?

Our military services have many decades of experiences with hose assemblies — and they are used under some of the worst conditions imaginable. Our military forces have distilled their experiences into procedures that are designed to keep our people safe. As users of similar kinds of hose assemblies, we can use these experiences and practices to keep ourselves safe. How do our armed forces manage hose life?

The U.S. Navy (USN) publications advise that aerospace polytetrafluoroethylene (PTFE) hose assemblies observe calendar based hose life limits. For example, the USN recommends replacing hose assemblies at the discretion of the local commander. In an ocean environment, it is recommended to replace a hose assembly seven years after date of manufacture.

The U.S. Air Force (USAF) recommends replacing PTFE hose assemblies “on-condition.”

The Air Force Technical Order 42E1-1-1 document requires that all aircraft rubber hose assemblies shall be replaced after 10 years of service as indicated on the identification tag. Any hose assembly that does not have an identification tag must be replaced.

Table 1 (Page 21) lists the several aerospace PTFE hose types and the storage and operational service recommendations adopted by military users. The operational life span promoted by the USAF and USN documents is in addition to the time spent in storage.

Table 1 lists several military documents as they apply to the PTFE tube-equipped stainless-steel wire reinforced aerospace hose assemblies. The USN recognizes that ocean air attacks hose reinforcement and has created policies for safety reasons. Now, what is meant by “on-condition?”

The aerospace hose users have established “on-condition” maintenance criteria to evaluate if a hose assembly is suitable for continued service. The user community has developed criteria from their experiences. The users advise that aerospace hose failure during operation is a very rare thing.

On-condition inspections

The owner/operator decides when to remove and replace based on the appearance and proof test performance of the hose assembly. The current practice is to remove and replace aerospace hose assemblies based “on-condition.” As practiced above, any hose assembly that does not have an identification tag shall be replaced immediately because its pedigree is not known.

Best practice: Sometimes a hose assembly is removed from the installation to ease maintenance of nearby or associated components. The mechanic should take the opportunity to inspect and proof pressure test the hose assembly to assure continued good service.

The mechanics report the most common reason for hose assembly removal and replacement is damage to the B-nut thread or to the fitting’s sealing surface. The on-condition inspection requires looking at the color of the metallic reinforcement and at the cover and the jackets and at the fitting parts. All of these parts must be free of burns, cuts, and other damage. The final on-condition inspection includes doing a proof pressure test. The hose assembly may then be returned to service, only if it passes these steps.

What “on-condition” means at a commercial operator

When an engine comes into the engine shop, the mechanics perform the following steps:

- Removes external items such as tub and hose assemblies from the engine

- Cleans the tube and hose assemblies and sends them to the inspection point

- Inspects the tube and hose assemblies for damage and segregates them into serviceable and unserviceable units and disposes of the unserviceable assemblies

- Proof pressure testing assemblies and tubes that pass the visual inspection

- Stages the assemblies and tube that pass proof test onto racks by part number for future use

The copyrighted SAE AIR1388 and AIR1569 and ARP 994 documents ought to be in your maintenance library. These are available for purchase from the Society of Automotive Engineers. These documents provide the operator general guidance and examples to help determine whether to use or replace a particular hose assembly.

Suggestion from the industry

The hose is about two or three rungs below the user on the supply chain. It is very hard for a manufacturer to collect meaningful hose life information. The best people to talk to about hose life are the folks that do the inspection and maintenance. This is because they watch them “age.” In the ideal situation, the mechanic would send each hose assembly removed from service back to the manufacturer.

Then the manufacturer can collect the age and failure mode data for the life evaluation. The manufacturer can conduct a visual inspection and a proof pressure test to determine the condition of the hose assembly. If the hose assembly leaks, then it can be dissected to determine the failure mode.

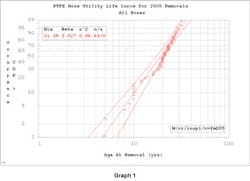

The analysis procedure will separate the failure mode data, evaluate it by age, and then construct the WEIBULL curve. The WEIBULL curve is a powerful tool that organizes data in a way that characterizes hose life.

Graph 1 is an example of a WEIBULL analysis. These samples were collected and returned to a manufacturer in 2005. The hose assemblies came from several engine and airframe service sites located around the country. Based on this sample of 63 assemblies built between the early 1970s and the early 2000s, we find the average age for a PTFE hose assembly is around 19 years old. The data was not analyzed in any other way. Nothing else can be said about this collection of hose assemblies.

Graph 1 illustrates how the data can be displayed after it has been collected. The WEIBULL graphs showing bearing life have been successfully used for decades. Similarly, a WEIBULL graph for hose life can be constructed for each application — if the data can be accurately reported.

Conclusion

The military organizations have established procedures for evaluating hose life, and in some cases have established fixed rules. For example, the Navy — on the discretion of the commander — may order that hose assemblies shall be replaced after seven years from date of assembly manufacture. The Air Force requires all rubber hose assemblies be replaced after 10 years from date of assembly manufacture, and PTFE hose assemblies shall be replaced “on-condition.” The Society of Automotive Engineers, Aerospace Section, has published several documents that help to illustrate what several types of hose damage look like.

How long should an aerospace hose assembly last? Unless the manufacturer receives accurate feedback from the users, we will never know. The tools needed to analyze the data are developed. The missing ingredient is the participation of the front line mechanics and users. Together we can find a way to answer the question.

Pete Stroempl is lead R&D engineer at Parker Hannifin Corp., Stratoflex Products Div., Fort Worth, TX.