Recommendations for Safe Baggage Handling

By Chris Barringer, head of transportation section, Health & Safety Executive

Musculoskeletal disorders (MSDs) — back injuries, sprains and strains — among workers have long been identified as a serious problem, and considerable improvements have been made in many industries. In Great Britain the Manual Handling Operations Regulations first came into force in 1993, implementing a European Directive.

While considerable improvements in managing MSDs have been achieved in some industries, HSE identified Air Transport as one of the highest risk industries for MSDs, with more than 51 percent of injuries at airports in 2001-02 caused by handling — that was more than 800 injuries. The main causes of these injuries were manual handling of baggage and cargo handling, with significant injuries also caused during the assistance of disabled passengers, either by use of inappropriate methods of lifting and moving disabled people, or in the loading/unloading of heavy equipment such as powered wheelchairs.

Many of the problems result from the design of airports and aircraft, and are not easily solved — for instance, cramped baggage halls and aircraft holds. Other factors include the weight of the load, rate of working and time pressures during turnaround, use of appropriate equipment and lifting aids, and good maintenance of equipment. We know we can’t change some of these things overnight, but the message is clear — the level of injuries to ground handlers is unacceptable, and we must start to reduce risks now. If we don’t act, the same risks will still be there in 10 years time, and these are costs the industry cannot afford.

One of the biggest problems is lack of investment in new equipment and technology, such as belt loaders and in-hold extending belt loaders and mechanized systems for handling bags in the baggage halls. Unfortunately, there has been a tendency for risks to be “contracted out” by airlines, and airports do not always consider the health and safety of workers when designing and building facilities. It is the ground handlers who bear these risks — but the whole industry ultimately pays the price.

In baggage handling it is the manual loading/unloading of bags both in the baggage halls and on the ramp where most injuries occur. HSE started to work with the industry through the Revitalising Health and Safety in Air Transport (RHSAT) initiative, and achieved some success in improving health and safety standards.

Bag weights were identified as a factor which could most easily be addressed, and in 2004, following a successful HSE/industry/trade union campaign to introduce the IATA-recommended 32-kilo bag weight limit, there was a measurable reduction in injuries. Unfortunately, this was not maintained. Provisional HSE accident figures for 2007-08 show that there were still more than 800 airport accidents caused by handling.

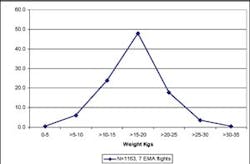

Although bag weights are still an issue, there has been a trend in recent years for airlines to impose lower baggage allowances and maximum bag weights. This has been aimed mainly at speeding up boarding and turnaround and to reduce aircraft weight and fuel costs, but also has benefits for handlers. IATA now recommends a 23-kilo bag weight limit, which has been adopted by many airlines. There are also recommendations for “heavy bag” labeling, and special arrangements for heavy or out-of-gauge baggage.

We fully support short-term solutions to reduce risks, but we also believe that the industry needs to look to the future to find long-term solutions to some of these problems. Lighter bags may help — but increased rate of handling can cause problems. Solutions will only be found if all parties — the airport operators, airlines and handlers — work together.

The fact remains that handlers are still dealing with heavy bags. Injuries can be caused by lifting or pulling a single unexpectedly heavy bag, or by working in the confined space of an aircraft hold. There is no “safe” weight for manual handling and repetitive handling of bags — even at 23 kilos or less — under the time pressure of short turnaround times, can still cause injury. These injuries can result in long-term pain and suffering, and inability to work, with the consequent costs to the worker and his family, the employer, the industry and to society.

The legal situation in the UK is quite clear:

- There are duties on employers and the self-employed to ensure, so far as is reasonably practicable, the health, safety and welfare at work of employees and persons not in their employment ( e.g., service providers) who may be affected by the undertaking

- The Manual Handling Operations Regulations set out the duties on employers to avoid risky manual handling operations where possible, and to reduce remaining risks by automation and use of lifting aids

- The Management Regulations set out requirements for risk assessment, information for employees on risks, and cooperation and coordination with other employers

- The Construction Regulations require designers and architects to design for safety and health for those that build, use, maintain and demolish — it’s safer by design

So, legally, the airports, airlines and ground handlers all have duties to control and reduce risks to workers, but there are underlying problems of lack of resources and investment. While there is intense competitive pressure for contracts, corners will be cut and, unless the airlines and airports also accept responsibility for the health and safety of airport workers, there are limits on the amount that ground handlers can do to resolve the problems.

HSE believes that the best way forward is to work in partnership with the industry to find solutions. However, injury numbers show that not enough was being done to reduce the risks, and HSE inspectors have taken enforcement action against handling companies for issues such as lack of belt loaders, and the use of unsuitable flatbed trailers which lead to risks both from manual handling, and from falls from the trailer which can cause serious injury.

Because there was still a lack of consistency in systems of work and understanding what “good practice” actually looks like, HSE agreed to fund a research project on one of the highest risk activities — the manual loading of bags into narrow-bodied aircraft.

We also agreed that the industry would take the findings of this research and, with HSE support, develop industry good-practice guidance. This guidance would provide clarity and consistency for the industry and the regulator, and ensure a level playing field for service providers at all GB airports. The research reports were published in December 2008.

There has been a great deal of research done into baggage handling and our initial work involved a literature review to establish current knowledge and intelligence. The evidence presented in this report, and other studies including previous work by the HSE (Tapley & Riley, 2005 and Riley, 2008) provides a strong case for the task to be redesigned or mechanized to reduce the risk of injury.

The on-site airport project was undertaken with the full support of East Midlands Airport, airlines, ground handlers, worker representatives and equipment manufacturers, with the agreed aim of identifying specific risk factors and assessing the benefits of different systems of work. We were given access to aircraft, and airport workers gave their time and expertise to help us assess equipment and work patterns. The experience of workers is key to this — they are the people who understand the problems, and often find the solutions. We were also very pleased with the cooperation of equipment manufacturers, who gave us access to equipment and information so that we could assess the benefits of new technology.

The study specifically considered systems of work for the manual loading of bags into narrow bodied aircraft — an activity identified as high risk due to operational constraints and aircraft hold design. The research identified a range of possible actions to reduce injuries and ill health. While lessons can be learned from this work, further work is necessary on baggage halls and other aspects of baggage handling.

RECOMMENDATIONS

The main recommendations of the report include:

- This study shows that extending belt loader (EBL) type technology significantly reduces musculoskeletal risks through the mechanization of the transfer of bags down the hold and improvements in posture and lifting. Therefore the GB aviation industry should consider using such technologies as a way to partly mechanize the task of handling baggage within the hold of the aircraft (NB: in-hold systems when used in combination with advanced belt loaders are considered to offer similar risk-control benefits)

- For the external on and off-load of bags the vertical level and lift distance of the bags is more favorable when using a belt loader compared to direct to hold loading from the ramp. Mechanical means should therefore be used in place of direct to hold loading wherever appropriate

- The high-risk manual movement of GSE should be avoided and the following methods of mechanization should be explored: pedestrian-controlled tugs, pedestrian-controlled powered GSE, and driveable GSE

- Means of risk reduction and control should also be explored for the other ancillary manual handling operations that handlers perform. For example, the baggage cart positioning, and the placement and collection of cones around the aircraft. Where some form of mechanical assistance is already in place, ensure that it is used. Further training and supervision may be required to achieve this

- A suitable means of access and egress to the aircraft for baggage handlers should be identified and provided, both in terms of avoiding falls and enabling effective working postures. For example, for staff working on flatbed lorries there is no edge protection and there is restricted headroom and footing, which leads to more twisting and sideways bending when handling

The findings of the research reports were considered by industry representatives at a meeting facilitated by the Institution of Occupational Safety & Health (IOSH) Aviation and Aerospace Group, with some very interesting results. The initial feedback from the workshops has now been circulated and will be available on the IOSH website.

The next stage is for the industry to agree on good practice and systems of work — HSE will support this work to ensure that the risks of MSDs in baggage handling are properly managed by all, at all GB airports.

Information on the air transport industry and on MSDs and assessment tools can be found on the HSE Web site at www.hse.gov.uk.

About HSE: The Health and Safety Executive (HSE) is responsible for the regulation of occupational health and safety in all workplaces in Great Britain. As part of the HSE Policy Group, Transportation Section is responsible for health and safety policy development and partnership working with industry sectors, employers, employee representatives and other regulators in air transport, ports, road haulage and warehousing.

Additional Links

Air Transport web pages

http://www.hse.gov.uk/airtransport/index.htm

HSE Manual Handling Assessment Chart (MAC) Tool

http://www.hse.gov.uk/msd/mac/index.htm

IOSH Aviation & Aerospace Group (AAG)

http://www.iosh.co.uk/index.cfm?go=groups.news&sgid=18

IOSH AAG event feedback

http://www.iosh.co.uk/index.cfm?go=groups.news_item&id=2512&sgid=18