Tools & Equipment: New Fall Protection Standards

Significant developments have occurred recently within Occupational Safety and Health Administration (OSHA) and American National Standards Institute (ANSI) safety standards that will have a significant effect on fall protection requirements throughout the aviation industry.

OSHA has gone through some considerable changes as a result of the Obama administration. Some changes occurring right now or soon to occur are:

- Increased focus on enforcement of OSHA law under the direction of OSHA’s new Assistant Secretary Dr. David Michaels.

- Decreased funding for voluntary protection programs (VPP). As of right now, the Senate has proposed that all funding be cut completely for the popular OSHA program which allows businesses to work directly with OSHA to increase employee protection voluntarily, before any citations or fines take place.

- The budget for OSHA will increase by 10 percent under Obama’s budget proposal.

- OSHA is imposing higher dollar value fines and pursuing proposed criminal prosecutions for “willful” violations.

- Money gained from the sum total of increasing the OSHA budget, raising the monetary value of fines, and directing money away from VPPs will be directed into hiring more field inspectors and increasing the number of OSHA inspections.

- A new law, “Protecting America’s Workers Act,” has been proposed to expand coverage of OSHA to include airline and railroad employees.

- OSHA is currently pursuing a major re-write of the 29 CFR Part 1910 for walking/working surfaces and fall protection systems.

New OSHA fall protection laws

OSHA has proposed many changes to the current law. The change of most importance to the aviation industry is the proposed wording change of the definition of “competent person.” Per OSHA law, all organizations that use fall protection must have a “competent person” who is responsible for the day-to-day use, training, inspection, monitoring, and enforcement of fall protection usage. The new proposed OSHA law reduces some of the enforcement requirements of the competent person.

At first this seems counterintuitive because reducing enforcement at the competent person level may appear to lead to unsafe practices. The intent, however, is not to reduce safety but to shift responsibility, and legal liability, more directly onto management and business owners. The objective is to both shield the competent person, who generally tends to be a blue collar worker or supervisor, from negligence lawsuits, and focus responsibility of enforcement more directly onto upper management and business owners.

The new leadership in Washington and OSHA has made it perfectly clear that safety violations will become more punitive in the future with higher fines and stronger and swifter criminal prosecutions for “willful” violations via the “Protecting America’s Workers Act.”

ANSI safety standards

ANSI, on the other hand, has been hard at work developing new equipment and user standards that increase the safety of fall protection equipment and the safety of workers using fall protection.

Although ANSI is a voluntary standard and not federal law, OSHA can site ANSI as a “nationally recognized safety standard” and hence a requirement for providing working safety under OSHA’s “General Duty Clause” OSHA Section 5(a)(1).

Here are some new developments from ANSI that would be of interest to the aircraft maintenance industry.

- ANSI Z359.1, which has been the original fall protection code from 1992 until present, will slowly be “phased out,” as the new ANSI standards Z359.0 and Z359.2 through Z359.18 will take its place. As of today’s date the following new standards have been released: (ASSE stands for American Society of Safety Engineers; it is the secretariat of the ANSI Z359 standard. ASSE members write and maintain the standard.)

- ANSI/ASSE Z359.0-2007: Definitions and Nomenclature Used for Fall Protection and Fall Arrest;

- ANSI/ASSE Z359.1-2007: Safety Requirements for Personal Fall Arrest Systems, Subsystems and Components;

- ANSI/ASSE Z359.2-2007: Minimum Requirements for a Comprehensive Managed Fall Protection Program;

- ANSI/ASSE Z359.3-2007: Safety Requirements for Positioning and Travel Restraint Systems;

- ANSI/ASSE Z359.4-2007: Safety Requirements for Assisted-Rescue and Self-Rescue Systems, Subsystems and Components;

- ANSI/ASSE Z359.6-2009: Safety Requirements & Specifications for Personal Fall Arrest Systems;

- ANSI/ASSE Z359.12-2009: Safety Requirements for connecting components for Personal Fall Arrest Systems; and

- ANSI/ASSE Z359.13-2009: Safety Requirements for lanyards and energy absorbers for Personal Fall Arrest Systems.

Although the changes are numerous, I will highlight changes that may be of most significance to the aircraft maintenance community:

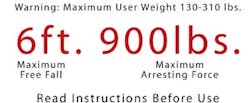

ANSI Z359.13 requires new labeling on energy-absorbing lanyards (commonly called “rip-stitch” or “shock pack” lanyards). This is most important to users of “vacuum anchors” attached to fuselages or tops of wings, or when workers need to tie off at foot level. It is very important to note that the attachment at foot level of a 72-inch-long energy-absorbing lanyard will result in a free-fall of about 12 feet. This causes a serious injury hazard if the worker unknowingly uses a lanyard capable of absorbing only a 6-foot free-fall (the most common lanyard). With the new labeling, the user will now be able to easily identify the 12-foot free-fall lanyard from the 6-foot free-fall lanyard (Figure 1 and 2). (Please note that the 6-foot free-fall capable lanyard, that is 72 inches long, is only allowed when the tie-off point is at the D-ring elevation or higher (Figure 3)). Consult with your vacuum anchor supplier or lanyard supplier for more information.

Hazard analysis and rescue plan

Also of importance to the aircraft maintenance industry is Z359.2, which is a new ANSI “user” standard that requires a hazard analysis and rescue plan be developed for every instance of fall protection. This is of significant importance in keeping your employees safe while wearing fall protection.

Common issues that potentially result in hospital visits after a fall event, even when using fall protection, are improper calculation of fall distance, failure to recognize injury hazards impacted during a fall, and swing fall injuries.

Improperly calculated fall distance can result in the user hitting a lower level. This can occur when either one of the following occurs:

a) 18-foot 6-inch clearance from the attachment point is not provided when using the common 72-inch-long energy-absorbing lanyard.

b) Wire rope flex is not taken into account on horizontal wire rope systems. Flexible wire ropes will deflect downward significantly during a fall event. For example, a commonly available 100-foot-long wire rope system may deflect 12 feet or more during a fall event. This 12-foot deflection added to the 18-foot 6-inch clearance from the attachment point requires about 30 feet of clearance when using a 72-inch-long energy-absorbing lanyard.

Swing fall injuries can occur when the attachment point is not directly over the worker’s head. If the attachment point is not directly over the worker’s head, the fall can result in the worker being “swung” or “pulled” back into the work platform quite violently.

New developments have been made in equipment and fall protection systems that “engineer out” the dangers of fall distance and swing falls that can affect aircraft maintenance workers who need to climb onto aircraft. One way this can be accomplished is with a rigid track “traveling bridge” used in conjunction with a self-retracting lanyard that continually retracts, like a seat belt, to minimize fall distance. The traveling bridge is designed out of lightweight high-strength steel or aluminum so it rolls freely along the runways. When the worker walks along the bridge the trolley follows the worker perfectly overhead without effort.

Because the trolley always remains directly over the top of the worker’s head, this eliminates the swing fall effect. Any fall event will be “straight down” resulting in no injury to either the worker or the aircraft.

This combination of the traveling bridge with the self-retracting lanyard provides the least amount of fall distance, eliminates swing falls, and provides the safest possible solution for the worker who needs to perform maintenance on aircraft at height.

To summarize, there have been many developments to keep aircraft maintenance workers safe, both in new regulations and in new equipment technology. To keep your workers protected, follow the new regulations and seek a fall protection system that best fits your particular needs and your maintenance operation.

Arnold Timothy Galpin, P.E., is engineering manager for SPANCO Inc., a company that specializes in fall protection equipment. He spoke earlier this year at Cygnus Aviation Expo in Las Vegas. For more information visit www.spanco.com.