Airframe Technology: Finding Intermittent Faults in Aging Aircraft Systems

Most aviation maintenance technicians (AMTs) would probably agree that intermittent faults are our nemesis and that finding and clearing those faults in aging aircraft is extremely problematic. The resources involved in endless troubleshooting and LRU swapping has a huge impact on manpower allocation and budgets. Even with significant investments, we have to question how successful we are at identifying and fixing intermittent faults in aging aircraft. The answer depends on the metrics. We aren’t doing so well if we use first time fixes, no fault found (NFF), cannot duplicate (CND) logbook entries and LRUs replacements as the measure of our effectiveness. There also may be a good argument that we are part of the problem.

Troubleshooting our troubleshooting processes

The problem would not be individual AMTs but the maintenance culture with its troubleshooting models, methods, and technology. It appears that this is not new news and there are others in our industry that holds similar views. In a June 1997 article in Avionics Magazine, Walter Shawlee II, president and founder of Northern Airborne Technologies Ltd. of Kelowna, British Columbia, presents an excellent assessment of our testing practices and their limitations. He suggests that “the nature and design of the test predetermines the result. Test strategies have traditionally tended to be serial and linear with isolated steps that progress over time and terminate in a go/no-go decision.

"However, it makes the highly erroneous supposition that faults exist as discreet situations of constant duration and merely presenting the right test conditions will make the fault unambiguously known. The origin of this strategy is one of convenience, but it entrenches complex faults and intermittent problems in the test system itself making them impossible to discover or correct in the field.” Shawlee also suggests that diagnostic systems may amplify the problem. He states that “the trend to eliminate any step during testing that requires human intervention may have initial economic or conceptual appeal, but may simply set the stage for downstream problems that will remain difficult or impossible to eradicate in the field.”

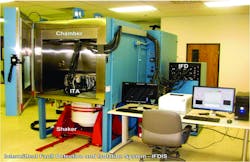

Universal Synaptics Corp.

There are experts in this field and one successful company specializes in troubleshooting intermittent faults in aging aircraft. Universal Synaptics Corp. has spent years in the field and lab researching and solving complex diagnostic and testing problems. Last fall it was recognized for its efforts by the Department of Defense (DoD). On Nov. 16, 2010, Universal Synaptics announced that the Intermittent Fault Detection & Isolation System (IFDIS) had been selected as the Great Ideas Competition winner at the 2010 DoD Maintennace Symposium and Exhibition. In February 2011, the IFDIS was selected as a Tibbetts Award winner. The Tibbetts Award is given by the U.S. Small Business Administration to honor outstanding small businesses that participate in the SBA Small Business Innovation Research program.

Ken Anderson, vice president of sales and business development, is one of Universal Synaptics experts on intermittent faults and their various causes. I asked him why we have such a high rate of NFF and CND test results for these intermittent faults, especially on aging aircraft. He explains that “as integrated circuits (ICs) and other electronic discrete parts become increasingly capable and reliable, an ever growing portion of the electronic equipment maintenance problems encountered are not component failure. They are intermittent interconnectivity problems between the electronic piece parts, like connectors, solder joints, wiring, wire-wraps, printed circuit traces and vias, flex circuits, crimps, splices, and relays.

"Depending on what report you read 40 to 60 percent of all pilot-reported aircraft system malfunctions which occur in the air are troubleshooting challenges for the AMT during follow-on ground testing. In a typical avionics system, there are thousands of internal and external circuit conduction paths moving electrons through thousands more physical interconnection points which are all aging to some degree and will fail intermittently long before they fail permanently. It only takes one of these interconnection points reaching this condition to render the LRU or wiring system unreliable.” I asked Anderson if there is a solution to this problem. He suggests that first we need to clearly understand the problem.

Defining the challenge of troubleshooting intermittent faults

“This is a science problem, a test coverage problem, a probability problem,” he says. In order “to catch intermittent faults on the ground, you must have phenomenal testing speed (sensitivity) and 100 percent bandwidth.” Anderson’s position is that if we want to reduce NFF and CND repeats we have to change our mindset, methods, and technology. “We can employ the most skilled technicians and engineers with the most comprehensive maintenance data collection systems and likely reduce NFF to some degree.”

It appears that if AMTs are to significantly improve our score card, then we must be able to detect and identify intermittent faults as they manifest in real time. “The proper technology for the task must be able to test all of the failing system’s lines, all of the time, in a simultaneous and continuous fashion," Anderson says. Universal Synaptics Corp. has a product that can detect intermittent faults in real time.

Intermittent fault detection & isolation system (IFDIS)

The intermittent fault detection and isolation system (IFDIS) is state-of-the-art testing technology that is specifically designed to detect, isolate, and identify the root cause of an intermittent fault. When you place an LRU in the IFDIS it first “interrogates and stores the as-designed wiring configuration from a good unit and then based on that “gold” configuration, will detect any open, short, ohmic, impedance, drift, or miswiring problems in subsequent units under test (UUT).”

The IFDIS simulates the operating environment and can subject an LRU to -100 F to 350 F. Additionally, it has a 2,205-pound-foot vibration platform with a 2-inch peak to peak displacement and 78-inch/second velocity that can induce a range of vibrations. Once environmental testing begins, the IFDIS continuously and simultaneously monitors every single electrical path in the chassis.

“The IFD, intermittent fault detector, finds and isolates intermittent events, as short as 50 nanoseconds (0.00000005 seconds).” Once detected, the fault and its location is automatically documented and displayed to the technician via high resolution fault isolation graphics which show the exact circuit path and connection points that are intermittent. The IFDIS process allows the technician to surgically repair the root cause of the intermittent fault.

IFDIS as a technical solution for intermittent faults

Working with prime contractor Total Quality Systems (TQS) and the U.S. Air Force, Universal Synaptics has been able to return to service more than $26 million worth of flight hardware previously considered “unrepairable,” more than double the mean time between depot repairs (an additional savings of $1.3 million annually), while reducing maintenance squadron re-work by 50 percent. This was achieved by the IFDIS’s ability to quickly and correctly detect and isolate intermittent faults. Air Force technicians understood that repairing an intermittent circuit was not difficult; it was detecting and isolating the intermittency that presented the challenge. With IFDIS, that diagnostic challenge is gone.

I had an opportunity to discuss the IFDIS in greater detail with Sami Mansour, director of the 523rd Avionics Maintenance Squadron at Hill Air Force Base in Layton, UT. According to Mansour, there are two IFDIS at Hill; one is being used by 523rd Electronics Maintenance Squadron and the other by the Software Engineering Lab. He says that the IFDISs are easy to use and dependable.

With the IFDIS, it takes technicians about two hours to test a typical avionics LRU and test results as extremely reliable. Once the IFDIS identifies and isolates an intermittent circuit, open or short, the technician knows exactly what the problem is and where to go to fix it. It appears that the IFDIS and numbers are working for the 523rd. Mansour estimates that they have achieved more than a “12 times return on investment and that continues to grow.”

Becoming part of the solution

Accurately detecting and identifying intermittent faults is an industry level problem now and may become more problematic in the years ahead. Integration of systems is the trend in today’s new and emerging aircraft. This is achieved by using powerful centralized computer processors to manage avionics systems and shed LRUs. Additional innovations in aircraft sensing, cockpit displays, inter/intra aircraft wireless communications, and passenger management and entertainment systems are adding layers of sophistication to new aircraft like the G 650, B787, and F-22. This trend will not abate. Our aviation scientists, engineers, and manufacturers are closely following the advances in medical technology, graphene based materials, and nanotechnology.

I argue that we need to make structural changes in our maintenance culture in order to maintain these integrated microtechnologies. One change must be in the curriculum that we use to educate and develop our AMTs. They will need a solid foundation in subjects like physics, Boolean logic, computer science, data analysis, wireless and satellite communications systems, systems theory, systems architecture, root cause analysis, and paths of influence in order to diagnose problems in this level of technology.

A good portion of the AMT’s work will be brains-on data management and analysis enabled by a deep knowledge of system architecture and operations. Another change must be to overcome the limitations that our current troubleshooting procedures and test equipment impose. We need to listen to the voices of folks like Ken Anderson and Walter Shawlee II and quickly adopt testing technology that companies like Universal Synaptics are developing.

Today’s emerging aircraft like the G 650, B787, and F-22 will be tomorrow’s aging aircraft and if history is a guide, they will present us with troubleshooting problems that are much more complicated. I don’t think a hardcopy wiring schematic and my old multimeter will be up for that job.

Charles Chandler is an A&P based in Michigan. he received his training from the Spartan College of Aeronautics.

About the Author

Charles Chandler

Field Editor

Field Editor Charles Chandler has a Masters of Science Degree in Adult and Occupational Education with a major in Human Resources Development. He began his aviation career as a junior mechanic for American Airlines and retired after 27 years of service. After leaving American he held both line and staff positions in six other major companies. His positions with those companies included curriculum development specialist, manager and director for organizational development, management and leadership development, and maintenance training operations departments.